Movements, deformations or settlements of ground structures can be monitored with geo-inclinometers. You can find out more about how the inclinometers work and how they can be used in our blog post.

Geotechnical inclinometers are precise measuring devices that are used to monitor ground movements and deformations in buildings and geostructures. They are used to recognise potential dangers such as landslides, foundation failure or subsidence at an early stage. In safety monitoring, they identify movements that could endanger buildings or people. The sensors can be used to support construction planning and the validation of ground stability models. They are also suitable for long-term monitoring, e.g. to check soil behaviour after the completion of construction projects (such as in mining or dams).

How geotechnical inclinometers work

Geotechnical inclinometers are primarily used to monitor ground movements, landslides and structural displacements. They often have to provide precise measurements under demanding conditions such as in boreholes, unstable soils or under water. These requirements lead to specific features that distinguish them from general inclinometers. Two types of inclinometers are particularly suitable for geotechnical applications: Electrolyte-based inclinometers and MEMS inclinometers.

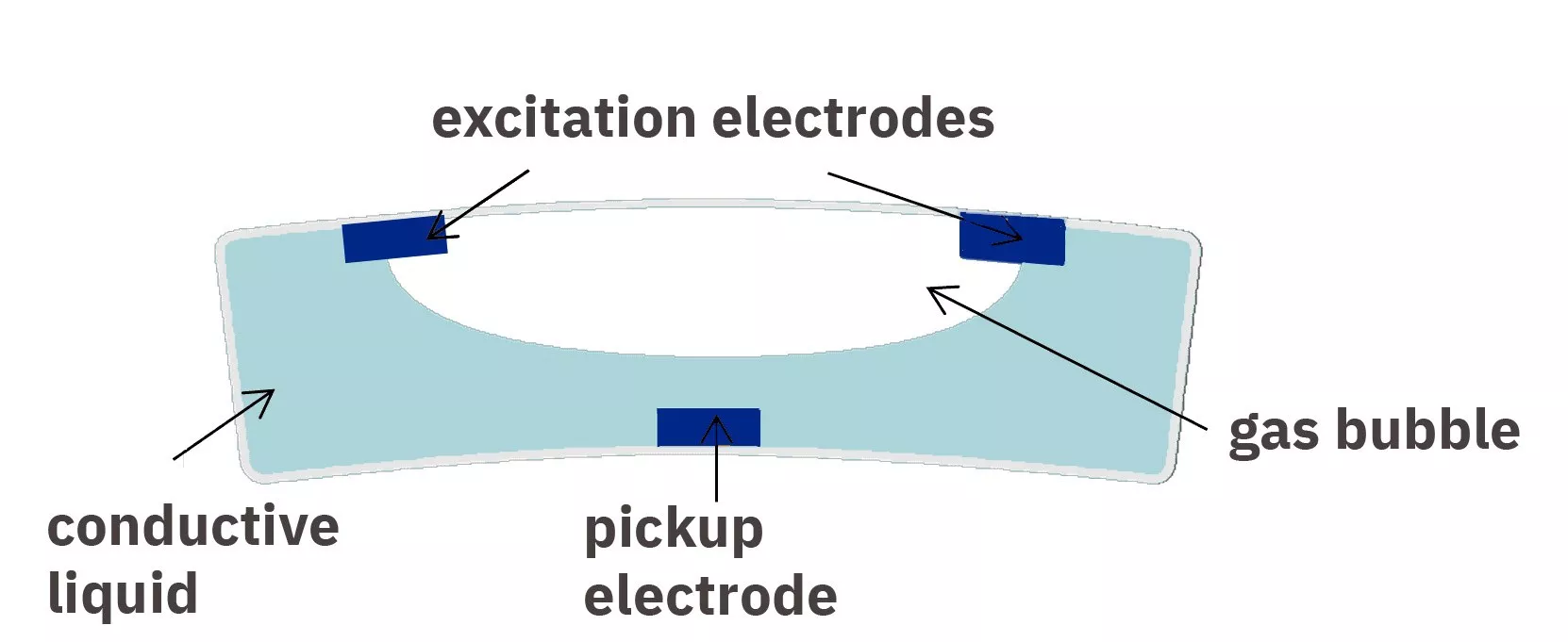

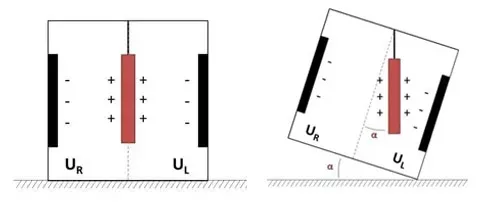

Electrolyte inclinometer

Electrolyte inclinometers are based on the change in the electrical resistance or capacitance of a conductive liquid when the inclination changes. The sensor consists of a container with an electrolyte solution and two or more electrodes that are immersed in the liquid. An AC voltage source measures the conductivity or capacitance between the electrodes. When the inclinometer tilts, the liquid level changes relative to the electrodes, resulting in a change in resistance or capacitance. This change is recorded electronically and converted into an inclination angle.

Electrolyte inclinometers are characterised by high sensitivity and repeatability and function without mechanically moving parts, which extends their service life. However, the so-called settling time has a disadvantageous effect. This is the time required by the measuring system to deliver a stable and precise measured value after a change in position or movement. This time is mainly determined by the behaviour of the electrolyte solution and the electronics. After a movement, for example, there may be brief oscillations or a delay until the liquid has calmed down. In addition, the electronics may require a certain amount of time to stabilise the measured values and filter out any interference. Electrolyte inclinometers are therefore not suitable for areas with strong vibrations.

MEMS inclinometer

MEMS inclinometers measure inclination angles using micromechanical sensors (Micro-Electro-Mechanical Systems). They are based on tiny capacitive or piezoresistive structures that move under the influence of gravity. This movement changes either the capacitance or the electrical resistance, which is recorded electronically and converted into an inclination angle. MEMS inclinometers are compact, robust and enable fast, precise measurements.

One disadvantage of MEMS inclinometers in geotechnical applications is their lower long-term stability and higher temperature sensitivity compared to liquid or precision inclinometers. Over long periods of time, thermal drift, mechanical stress and ageing of the sensor components can lead to measurement deviations. In addition, non-linearity and accuracy are generally somewhat worse than with electrolyte inclinometers.

Use of inclinometers

Measurements with geotechnical inclinometers can be carried out by attaching the sensors directly to the structure to be monitored, for example to walls, floors, dams or other surfaces. This offers the advantage of simple and direct installation and is particularly suitable for short-term monitoring or when precise movements on a specific surface need to be recorded.

If ground or structural movements need to be monitored at depth, a borehole is required. Ground movements, landslides or subsidence do not only occur on the surface, but often in deeper layers. A borehole allows the measuring tube to be positioned at the relevant depth. The inclinometer consists of a probe that is moved along a specially lined measuring tube guide in the borehole. These probes are particularly suitable for long-term measurements as they are better protected against environmental influences.

Categories of inclination sensors

The sensors measure the inclination of the surface on which they are mounted in one or more axes. Changes in inclination over time provide indications of movement, deformation or settlement of the structure. Our geotechnical inclinometers can be divided into four categories: Standard inclinometers, precision inclinometers, ultra-precision inclinometers and miniature inclinometers.

Standard transducers

Standard transducers include MEMS inclinometers and transducers with a non-linearity of 0.05 - 2.5 (% FRO maximum) with one or two axes. They typically have larger measuring ranges, while precision and ultra-precision inclinometers are designed for smaller angular ranges to ensure higher accuracy. Standard inclinometers can be operated in a wider temperature range. They provide an effective inclinometer solution for levelling/positioning platforms, monitoring structures, monitoring buildings or even positioning industrial machinery.

Product examples:

Precision inclinometers

Our precision inclinometers have a resolution of 0.0001° or better and can detect even very small changes in angle. They are electrolytic inclinometers and are primarily suitable for structural monitoring, levelling of platforms and industrial measurement and control. Another important feature is the very low drift over long periods of time.

Product examples:

High and ultra-high precision inclinometers

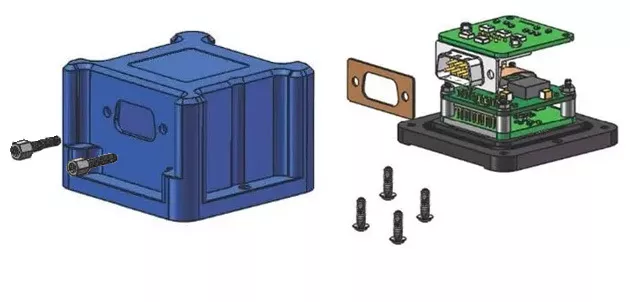

High and ultra-high precision inclinometers often have a narrower bandwidth and longer response times as they are optimised for measuring very slow changes in inclination. They can detect the finest changes in angle while at the same time being extremely robust. These inclinometers are often specified for a narrower temperature range to ensure maximum accuracy. They are suitable for use in extreme conditions, for example in high-precision geotechnical applications such as volcano monitoring, precision metrology, oil and gas, bridge monitoring or robotics.

Product examples:

Miniature inclinometers

Our miniature inclinometers are specially designed for applications where space is limited. They offer compact dimensions combined with high performance and are also electrolyte-based. Typical applications for these compact sensors include X-ray mirrors, telescope mounts, wind tunnel models and medical devices. With a suitable amplifier, these inclination sensors can be operated at a distance (cable length from the amplifier) of up to 100 metres.

Product examples:

Installing the sensors

Most inclinometer sensors are mounted directly on the surface to be monitored. Depending on the nature of the surface, this can be done by screwing, gluing or magnetic attachment. For monitoring over larger areas, the sensors are often installed in a row and mechanically connected to each other in order to record continuous data along a line.

Connection and data transmission

The sensors are typically linked to a central data acquisition unit via cables or wireless connections. The measured data is transmitted to a monitoring system in real time or at set intervals. Continuous monitoring makes it possible to detect and analyse even the smallest displacements or deformations. Comparative measurements over time help to identify movement patterns and assess potential hazards.

Challenges and limitations

When using geo-inclinometers, a number of requirements must be met in order to obtain an optimal measurement result. As they have a certain sensitivity to temperature changes, extreme temperatures can influence the measurement result. They are particularly suitable for measuring inclination over shorter distances, as the accuracy of the measurement decreases over longer distances. The latter also depends on the soil conditions. In very loose or highly compressed soils, installation is more difficult and the measurement result may be inaccurate. Strong vibrations, e.g. from machines, can also affect the measurement. Geo-inclinometers are also only suitable to a limited extent for rapid changes or dynamic movements of the ground, such as rapid subsidence or earthquakes. The reaction speed of the sensors may be limited here.

Project examples

Volcano monitoring

Inclinometers have long been used to study active volcanoes by observing their shape change before and during an eruption. When pressurised magma enters the magma chamber beneath a volcano, the ground is pushed upwards, causing the slopes of the volcano to tilt away from the centre of the uplift. Before an eruption, the magma flows to the surface, emptying the magma chamber and reversing the direction of the tilt. This characteristic behaviour, combined with measurements of earthquake frequency and magnitude, is successfully used by volcanologists around the world to predict eruptions hours to days before the actual event. As the magnitudes of the surface inclination can be very small, high-precision inclinometers such as the 700 series are used for these measurements.

Geophysical research

The Carnegie Institution of Washington installed two Jewell Instruments Model 510 geodetic borehole inclinometers (now 500 Series Tiltmeters) on the seafloor east of Japan. The scientists are attempting to establish long-term seafloor observatories in one of the most active earthquake zones in the world. Each observatory contains a Jewell Model 510, a geodetic borehole inclinometer, a Sacks-Everston borehole strain meter, two seismometers and a temperature sensor. The installation was carried out from the research vessel JOIDES Resolution. In the region known as the Japan Trench, the Pacific plate collides with the Eurasian plate and slides under it, a process known as subduction. Subduction zones are the places on Earth where the largest earthquakes occur. Monitoring seismic and aseismic deformation over time will allow scientists to understand how and when stress is released in the Japan Trench.

Typical areas of application for geotechnical inclinometers

- Wall monitoring: Checking retaining walls or building façades for deformations.

- Soil monitoring: Measurement of subsidence or heave in floor slabs or traffic areas.

- Dams and bridges: Monitoring deformations on critical structures without invasive measures such as drilling.

- Excavations and foundation monitoring: Monitoring of movements in deep excavations.

- Slopes and dams: Detection of landslides or displacements in dams.

- Tunnels and underground construction: Ensuring the stability of underground structures.

- Earthquake protection: Monitoring ground reactions to seismic activity.

- Mining and open-cast mining: Monitoring the stability of spoil heaps and pit walls.

- Levelling of platforms / radar and antenna position control

- Industrial measurement and control

Selecting a suitable geo-inclinometer

The selection of a suitable geotechnical inclinometer depends on various factors, including the required measurement accuracy, the area of application, the installation method, data recording and transmission, and the price.

Firstly, measurement accuracy and resolution play a decisive role. While an accuracy of ±0.1° is sufficient for rough monitoring, accuracies of ±0.001° are required for high-precision measurements, for example when monitoring dams or tunnels. Equally important is the choice of inclinometer itself. MEMS-based inclinometers are compact and cost-effective, but have lower long-term stability and higher temperature sensitivity, while electrolyte-based inclinometers have high sensitivity and repeatability. However, they are only suitable to a limited extent for strong vibrations.

The area of application and the environmental conditions also determine the requirements for the device. While particular attention must be paid to stability and long-term precision when monitoring buildings, robust, weatherproof sensors are required for monitoring landslides or embankments. In tunnelling or mining, the devices must be able to withstand vibrations, and seismic measurements require high sampling rates and high sensitivity to rapid movements.

Another important aspect is the installation method. Inclinometers can either be installed in boreholes to measure deeper ground movements or attached directly to the surface of structures to detect changes in inclination. Wireless systems are particularly advantageous for areas that are difficult to access. Data recording and transmission should also be considered. Depending on the application, real-time data transmission via LoRa, GSM or WLAN may be required, especially for early warning systems. Alternatively, logger-based systems can be used that store measured values on site and are read out periodically. It should also be checked whether the inclinometer can be integrated into existing geotechnical monitoring systems.

In addition to the technical requirements, the budget also plays a decisive role. Mechanical inclinometers are the most cost-effective solution with prices between €100 and €1,000, while MEMS systems cost between €200 and €5,000 depending on their accuracy. Optical systems offer the highest precision, but are also the most expensive option with prices ranging from €5,000 to over €50,000. Finally, maintenance and long-term stability should be considered. While some systems need to be calibrated regularly, others offer high resistance to drift and environmental influences.

Geotechnical inclinometers for climate-related applications

Geotechnical inclinometers play an important role in overcoming the challenges posed by climate change. They help to monitor and manage the impact on natural and built environments by measuring movements and deformations in various structures and geological formati

In permafrost areas, which are increasingly thawing due to global warming, inclinometers monitor ground movements and subsidence in order to recognise signs of instability at an early stage. This helps to prevent or minimise damage to infrastructure such as roads, pipelines and buildings. They are also of great importance in coastal and slope areas: by detecting changes in inclination, they can predict potential landslides caused by extreme weather events or rising sea levels at an early stage. This data is crucial for identifying areas at risk and planning protective measures such as coastal defences or evacuations.

Dams and flood defences are also common locations for inclinometers, as changing precipitation patterns and extreme weather events increase the load on these structures. Here, they measure structural deformations that can be caused by rising water pressure and help to ensure the safety of the facilities in order to prevent disasters such as dam failures. Similarly important is their use in mining and open-cast mining areas, where they monitor movements in embankments and enable the timely detection of instabilities. This protects both employees and the environment.

Inclinometers also support the expansion of renewable energies by monitoring ground movements at the sites of wind turbines, solar fields or geothermal plants. This ensures that these plants remain stable and efficient even when ground conditions change. In mountainous regions with an increased risk of landslides triggered by more frequent heavy rainfall events, they recognise shifts in slopes that could indicate impending landslides.