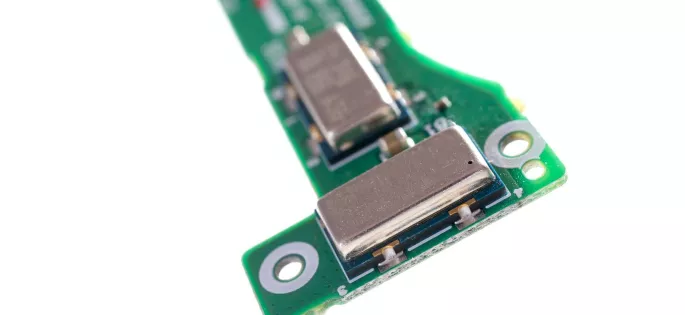

MEMS technology sensors are low-cost, high-precision inertial sensors that can be used to serve a wide variety of industry applications. Micro-Electro-Mechanical Systems (MEMS) technology involves the integration of mechanical elements, sensors, actuators, and electronics on a common silicon substrate through microfabrication technology.

Introduction to MEMS Technology and MEMS Sensors

Micro-Electro-Mechanical Systems (MEMS) technology involves the integration of mechanical elements, sensors, actuators, and electronics on a common silicon substrate through microfabrication technology. MEMS devices can range from very simple structures with no moving elements to extremely complex electromechanical systems with multiple moving elements under the control of integrated microelectronics. MEMS sensors are a subclass of MEMS devices specifically designed to detect and measure physical phenomena. Common types of MEMS sensors include:

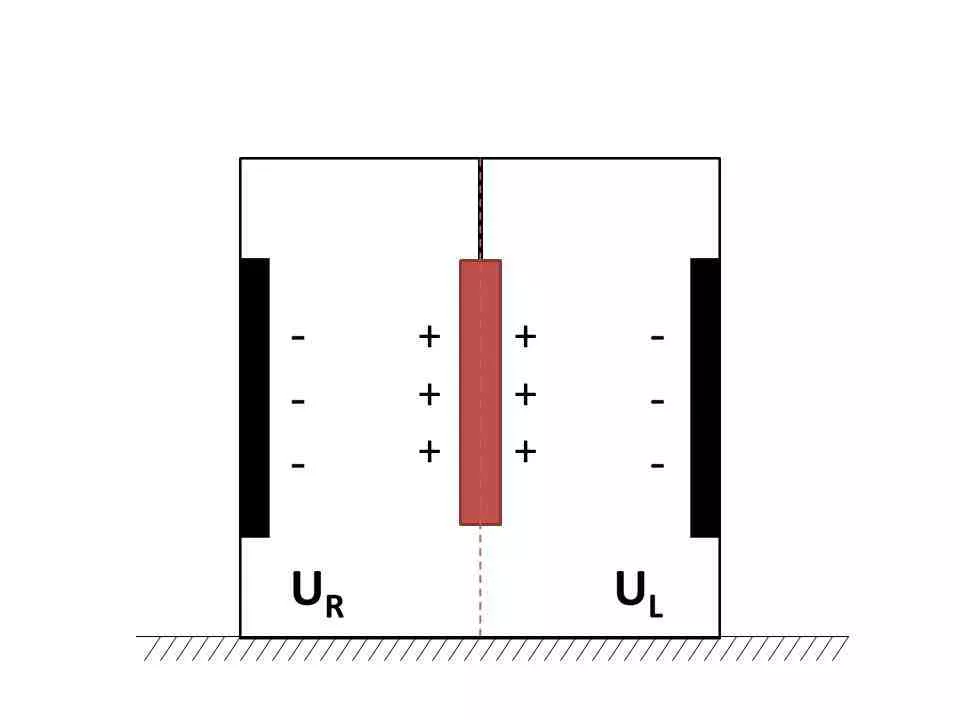

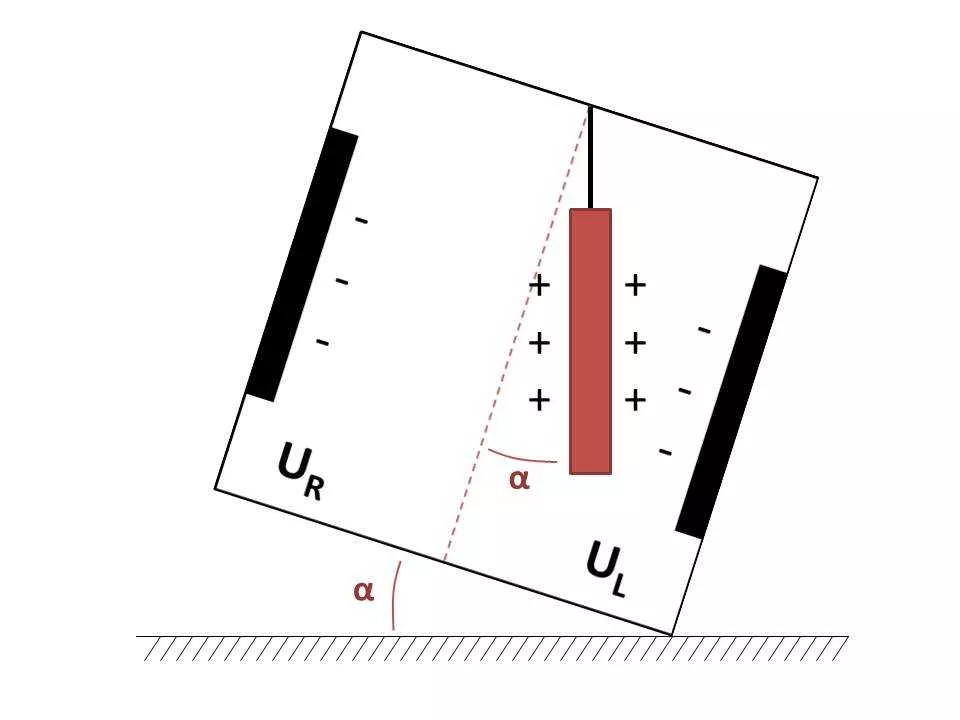

- Accelerometers: Measure acceleration forces, which can be used to detect orientation, vibration, and shock. They are widely used in smartphones, gaming controllers, and automotive airbag systems.

- Gyroscopes: Measure angular velocity or rotational speed. They are essential in navigation systems, mobile devices, and stabilization systems for cameras and drones.

- Pressure sensors: Detect changes in pressure and are used in various applications, such as weather monitoring, industrial process control, and medical devices.

Advantages of MEMS technology

MEMS technology does have some advantages of its own. Mems sensors provide convenient features available with every other sensor line without any space constraints. In addition, MEMS makes use of very compact micro machine components so tiny that each MEMS sensor can easily fit into the palm of your hand. Plus, MEMS sensors have an IP67 seal. This is because the sensors need to be able to withstand some intense temperatures ranging from 40º to +85ºC. Most industries in which MEMS sensors are used operate in extreme temperatures. And, this seal enables the sensors to be submerged into shallow water for temporary periods, allowing them to monitor the offshore and subsea pitch and roll applications. Other electrolytic sensors might have higher accuracy but are often more sensitive to temperature.

Shock and vibrations resistance

Another advantage of these MEMS sensors is their shock and vibrations resistance. MEMS sensors may not be the most persevering in shock absorbing environments but MEMS inclinometers have a vibration resistance of 10grms @ 10-1000Hz and accelerometers bear a shock resistance of 100G. So, these sensors are not to be used in highly shocking scenarios such as military applications but they can hold up to industrial measurements and control, drilling equipment and some geotechnical monitoring.

Our MEMS sensors

Limitations

However, MEMS technology sensors seem great yet they do have some limitations. In general, MEMS sensors often have a larger drift over temperature. This can be of concern for those who do not have temperature compensation or heating capabilities. And, relative to other traditional and more expensive sensors, MEMS sensor typically have lower precision. Therefore, you should always identify what it exactly is that you need to measure before purchase.

Many different fields and low cost

MEMS sensors are perfect for applications that do not need the highest accuracy such as industrial automation, platform leveling, position control and pitch and roll measurements. This is why MEMS electrolytic sensors are the perfect fit for many different fields and at a low cost.

Offering enhanced performance

MEMS technology and MEMS sensors represent a significant advancement in the miniaturization and integration of mechanical and electronic systems. Their widespread application across various industries highlights their versatility and importance. As technology continues to advance, MEMS devices are expected to become even more prevalent, offering enhanced performance and enabling new applications.