One of our previous blog posts dealt with the functionality of pressure measurement chains. Today, let's take a look at the information and specifications that you as a customer need to provide so that the right pressure measurement chain can be customised - using the example of an ‘engine test bench in the automotive sector’.

Applications

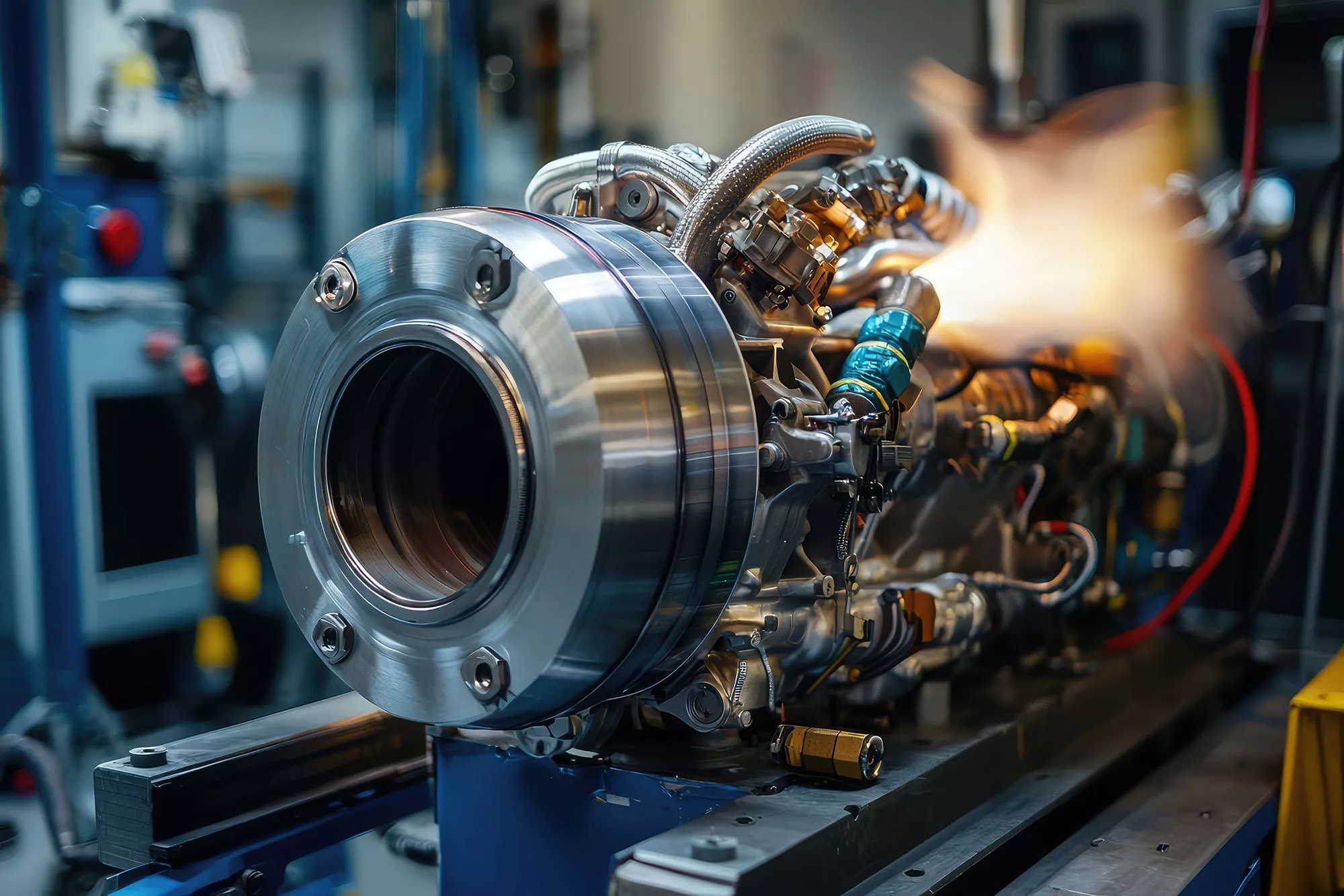

In test bench construction in the automotive sector, there are various applications in which pressures need to be recorded. In brake force distributors and ABS control units, for example, leakage measurements are carried out to assess the braking performance and efficiency of the system. In transmission test benches, the oil pressure must be recorded in order to check the functionality and lubrication. The measurements in engine test benches are carried out in various systems such as the intake and exhaust system, cooling and lubrication. The parameters include the intake air pressure, the exhaust gas pressure, the oil pressure in the engine, the coolant pressure in the cooling system and the temperature and pressure conditions in various cooling circuits.

These are often high-temperature applications for which only robust measuring systems are suitable - and therefore, in the case of pressure detection, only pressure sensors with an external measuring amplifier. Pressure sensors with an integrated amplifier are designed for a maximum temperature of 85 degrees Celsius. Such a scenario automatically requires a measuring chain consisting of a pressure sensor, measuring amplifier and suitable cable assembly. But how can the individual components be selected to harmonise with each other? We need a wide range of specifications and information from the customer in order to assemble the best possible pressure measurement chain.

Wide range of specifications

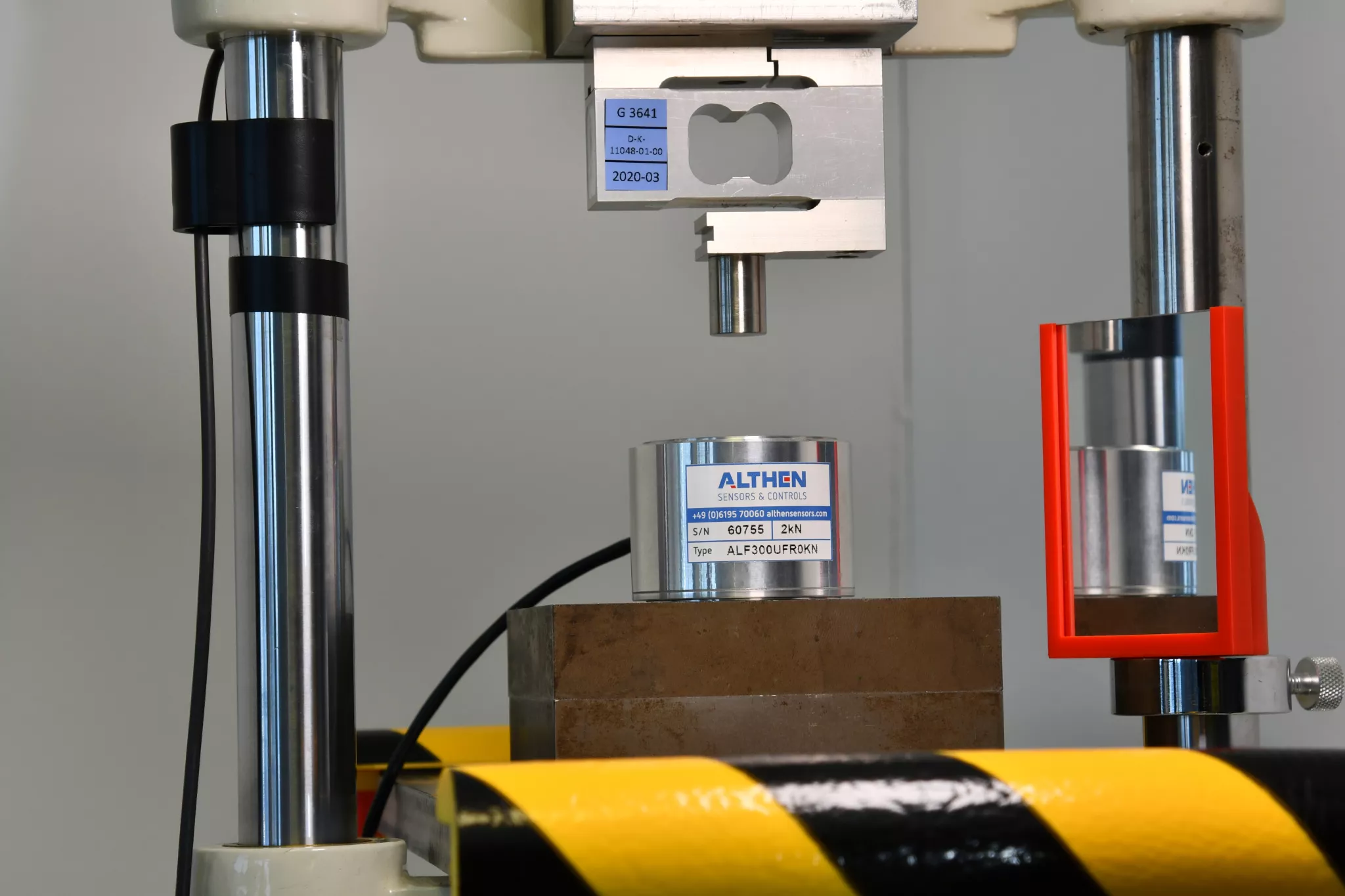

The selection of pressure transducers alone is large. The type of application can already narrow down the selection; is a standard transducer required for the industrial sector or a particularly robust sensor with special steels, e.g. for the aerospace industry? If the installation space is very limited, as is often the case in test bench construction, miniature pressure transducers are recommended. Fixed specifications that must be provided by the customer are the desired measuring range, the medium, the application temperature and the accuracy of the sensor. The latter is often not defined in advance by the customer, so we work closely with the customer's application engineers to determine the requirements and define suitable pressure transducers. Safety-critical applications require significantly higher accuracy than applications in which it is only necessary to determine whether the pressure is rising or falling. The application temperature determines whether pressure sensors with an integrated measuring amplifier are possible (< 85 °C) or whether a complete pressure measuring chain is required.

Customised measuring amplifiers

We manufacture the measuring amplifiers to suit the respective application. To do this, we need customer specifications such as the output signal (voltage or current) or the cut-off frequency to be measured. We also need to know whether the application is a dynamic one, where the pressures change very quickly, or a more static one. We can adapt the design, install an IP-protected housing for the measuring amplifier or provide for rail mounting, as is often required in test bench construction.

The final piece of the puzzle in the design of the pressure measurement chain is the cable assembly. We enquire about preferred electrical connections from the plug to the cable with free ends and need to know the cable length. Basically, the closer the pressure transducer and external amplifier are to each other, the better the electromagnetic compatibility (EMC).

Calibration standard according to customer requirements

Finally, the company's quality management team must determine which calibration the measuring chain should undergo. Depending on the application and safety-critical conditions, a decision is made as to whether a factory test certificate is sufficient, a calibration according to the DIN standard or a DAkkS calibration (German Accreditation Body) should be carried out. The latter describes the highest calibration standard with the highest accuracy. DAkkS calibrations and regular recalibrations are often required in test bench construction in the automotive industry.

When designing a pressure measurement chain, many small and large components must be taken into account in order to achieve meaningful measurement results for the application. We are always in close dialogue with our customers until all specifications are available and a customised pressure measurement chain can be assembled.

When designing a pressure measurement chain, many small and large components must be taken into account in order to achieve meaningful measurement results for the application. We are always in close dialogue with the customer until all specifications are available and a customised pressure measurement chain can be assembled.