Hand-operated joysticks, which can be controlled by the hand or by individual fingers, have found their way into a wide range of applications and industries. But not all joysticks are the same. What are the main differences, and what defines a high-quality joystick? In our overview article, we examine the functionality, design, and operation of industrial joysticks.

Joysticks are no longer limited to the gaming world. They have proven their value in many industrial applications. These control devices allow users to perform movements with greater precision and smoother control. They are widely used in sectors such as crane technology, industrial trucks, agricultural machinery, drones, cable hoists, and drilling platforms. In addition, joysticks are increasingly being integrated into installation engineering, robotics, and medical technology, such as in surgical robots.

Joystick for intuitive motion control

There are several alternatives to joysticks, such as buttons and membrane switches. Mechanical buttons and membrane keyboards, which consist of multiple membrane layers, close a circuit and activate a function when pressed. While these options are functional, joysticks offer much faster and more precise control.

Take, for example, a crane performing a vertical movement. When this motion is controlled solely by pressing a button, it is less intuitive for the operator than when the movement can be followed and guided with a joystick. Joysticks enable more direct and responsive interaction with the intended actions, making overall operation easier.

Sensitivity and haptics are crucial

Joysticks remain popular when it comes to finely controlling the movements of machines or vehicles on a small scale. A good joystick must meet two key requirements. On the one hand, it must provide precise control. On the other hand, it must feel comfortable in the hand for the specific application. This is critical, because an operator can only use a joystick effectively when its haptics and handling are well matched to the process involved.

Extensive configuration options

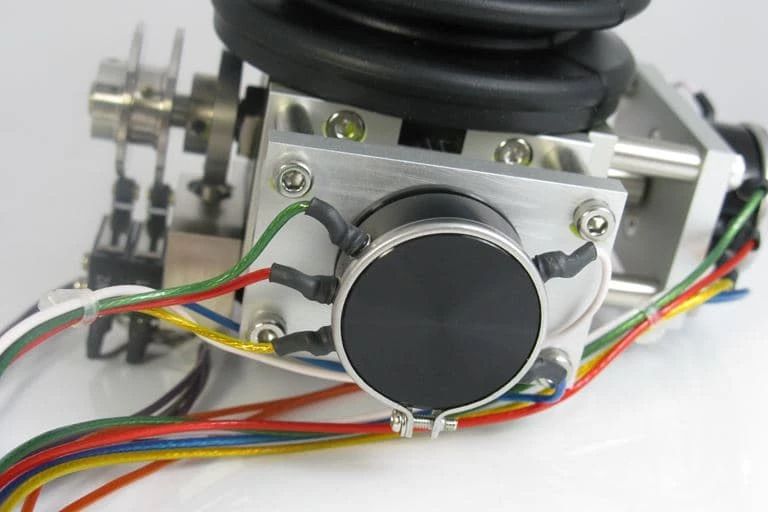

The world of joysticks offers a wide range of configuration possibilities. In general, there are two main types. The first are hand joysticks, which are usually equipped with a potentiometer for control. The second are more modern mini thumb or finger joysticks that use contactless sensor technology, such as Hall sensors. These are particularly durable because they significantly reduce mechanical wear.

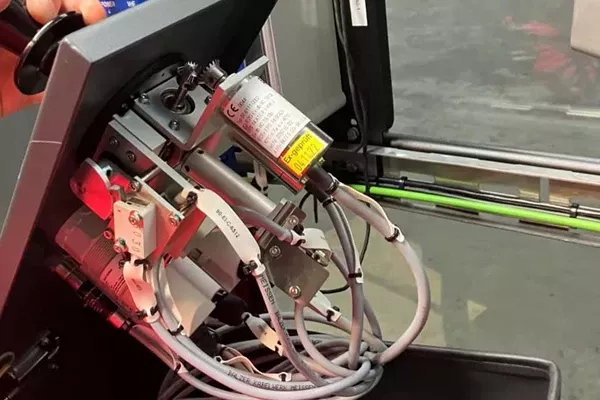

A special type of hand joystick is the Cobra joystick, named after its snake-like design. These proven joysticks also include push-button switches for more complex functions. In addition, numerous configuration options are available, including the number of axes, the shape of the handle, the design, and the materials used. Interfaces, additional functions such as buttons, protection classes, and industry-specific versions with ATEX certification are also possible, allowing these joysticks to meet a wide range of environmental requirements.

Make sure to test samples

Given the wide range of configuration options, testing joysticks is essential. This applies alongside a detailed specification sheet. It helps our control specialists meet customer requirements. It is important to develop a good feel for the device. Both functionality and ergonomics must be evaluated.

When an operator uses a joystick regularly, it must feel comfortable in the hand and must not cause strain. Companies that want to switch to joystick control can use this active trial and error approach. It helps convince staff to move from familiar button based systems to joystick control.

High accuracy

Switching to joysticks requires some investment, as they are typically more expensive than traditional button systems. However, they offer significant advantages, such as higher precision and better control.

When choosing a joystick, it is important to consider the specific application. The most advanced model is not always necessary. For example, a simple single-axis Hall-effect joystick may be perfectly adequate for controlling a hoof-trimming machine for livestock.

Delivery options and spare parts service

Our joysticks are designed for long-term durability and are custom configured to meet the specific requirements of your application. An important factor for our customers is delivery speed. We supply fully configured joysticks within two to three weeks and provide technical support whenever needed. In addition, we offer a spare parts service, which is mainly suitable for high-end models. For simpler joysticks, wear or defects usually lead to full replacement, depending on the operating environment. For example, in livestock farming, the rubber boots of simple joysticks used on hoof-trimming machines must be replaced regularly due to aggressive environmental factors such as animal waste, which causes rapid wear. Replacing the entire joystick would be too costly.

-

Precise and proportional controlJoysticks allow movements in multiple dimensions (X, Y, and sometimes Z axes) to be controlled simultaneously. This makes operating machines with complex motion requirements much easier.

-

Multi-directional operationJoysticks bieden de mogelijkheid om bewegingen in meerdere dimensies (X-, Y- en soms Z-as) gelijktijdig te besturen, waardoor het bedienen van machines met complexe bewegingsvereisten aanzienlijk gemakkelijker wordt.

-

Combined controlsIn many situations, joysticks can control multiple actions at the same time, such as rotating and moving a robotic arm simultaneously. This saves time and increases efficiency.

-

Flexibility and adaptabilityJoysticks can often be individually programmed or configured to perform specific actions or to meet application-specific requirements.

A perfect fit for every application

Joysticks provide a precise and intuitive way to control industrial motion sequences. Since every application has unique requirements, joystick configuration options are highly versatile. In a follow-up blog post, we will discuss key considerations when selecting a joystick and highlight the importance of haptics.