Temperature compensation strategy for miniature pressure sensors

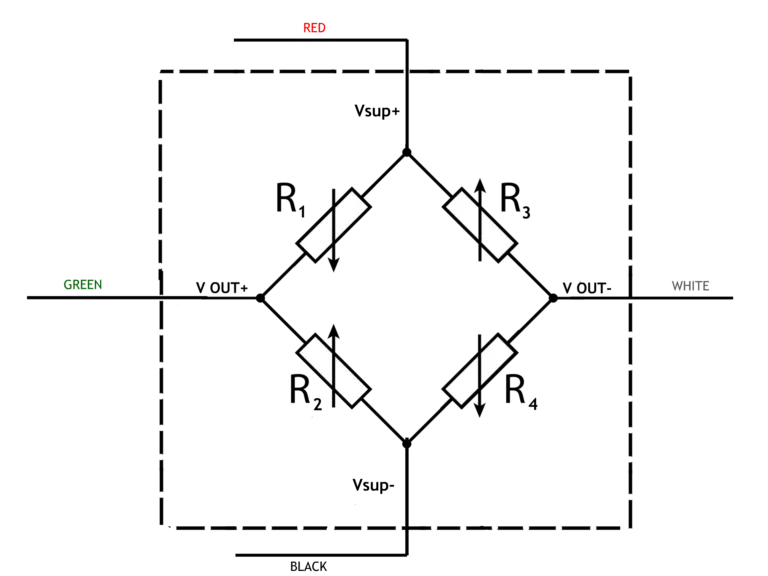

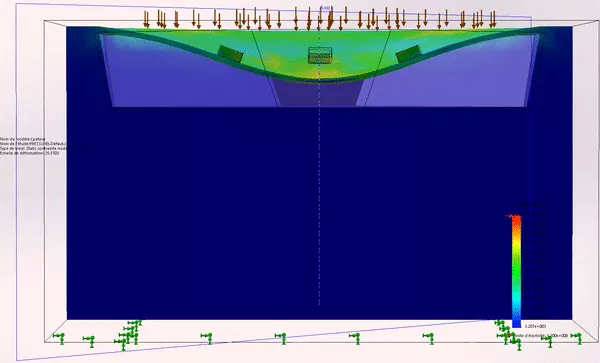

The pressure sensor operates as a Wheatstone bridge (see Figure 1), where the output voltage (Vout span = Vout+ – Vout-) corresponds to the pressure level, and the resistance of the bridge (R = (R1+R2) * (R3+R4)/(R1+R2+R3+R4)) reflects the temperature level.To obtain this information, we conduct various voltage output measurements using data derived from the deformation of the membrane. This deformation simultaneously affects all four resistances, altering their values to reflect the degree of membrane deformation, as illustrated in Figure 2. Measurements are taken under known conditions of pressure and temperature, within a fixed temperature range (from a defined minimum to maximum value).

Objective

This tutorial aims to outline strategies for measuring and compensating for temperature effects. Below is an overview of four approaches you can implement at your facilities:

- 4-Wire technique

- 6-Wire technique – Pressure Sensor Driven by Current

- 6-Wire technique – Pressure Sensor Driven by Voltage

- 6-Wire technique – Pressure Sensor Driven by Voltage via a Sensor Box

Each method offers distinct advantages and is suitable for specific applications, ensuring precise pressure measurement under varying environmental conditions.

- Figure 1: Wheatstone Bridge - 4 wires

- Figure 2: MEMS deformation

4-Wire technique

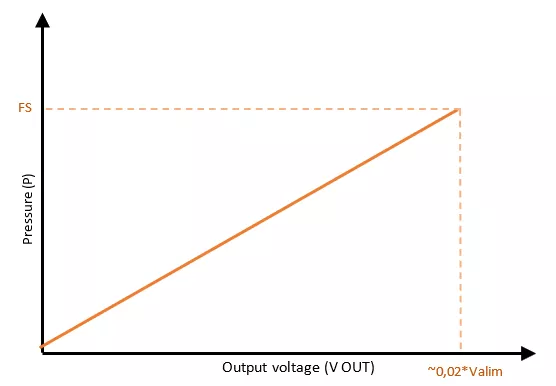

This method is best fitted when the application does not require high accuracy and/or does not have to sustain large temperature variation. In this case, we provide one curve to the user (Figure 3).

Equipment needed: an accurate power supply source, and an accurate Voltmeter.

Figure 3: Output voltage of the sensor according to the pressure

6 wire technique (current driven sensor)

For the 6-wire method, two additional wires are implemented on the sensor to facilitate temperature measurement with an accuracy of ±0.75°C. These wires enable temperature compensation by making measurements at various temperature levels. This approach is the most accurate and also provides the capability to measure temperature directly.

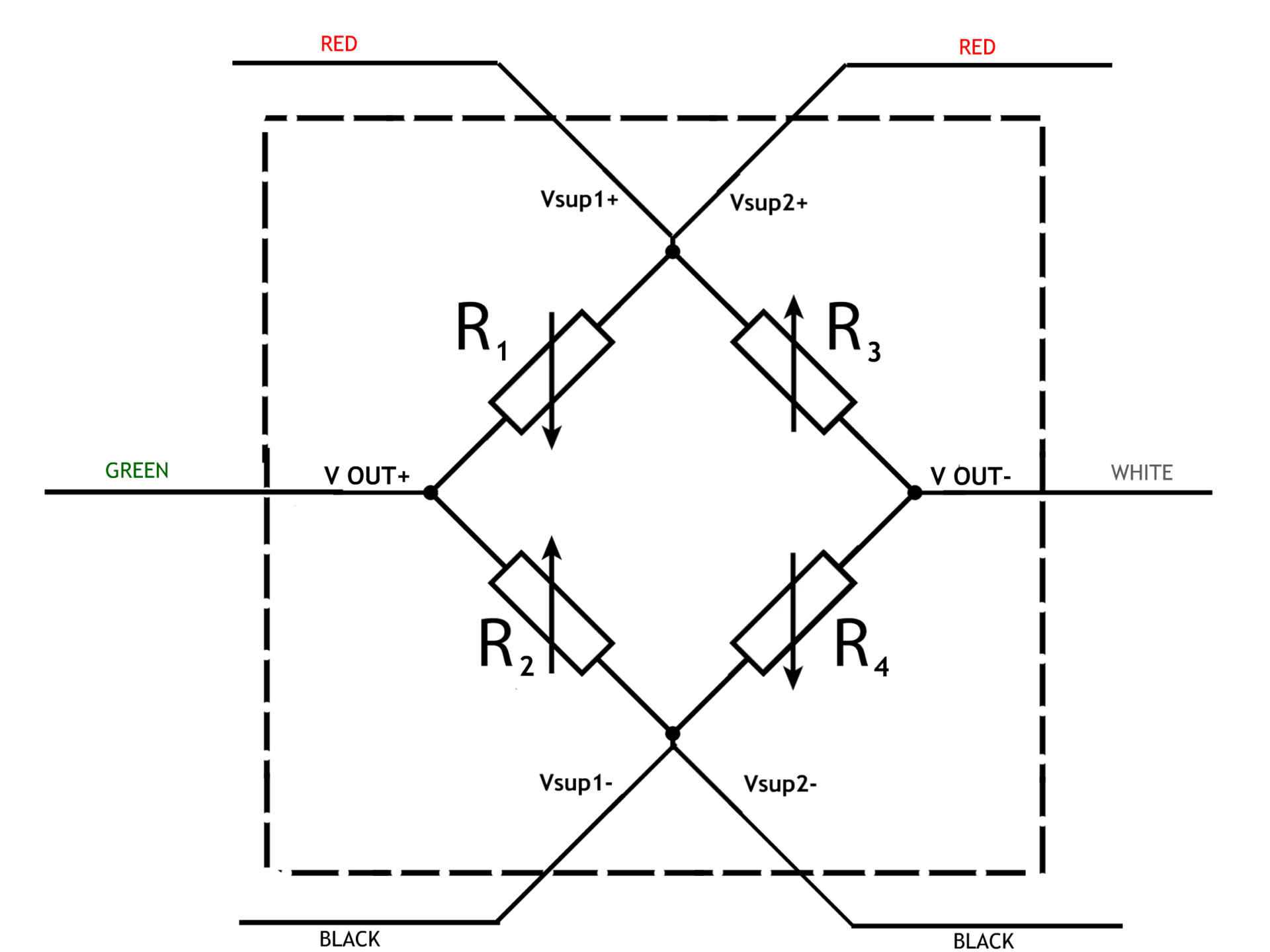

This method is best illustrated with a Wheatstone bridge circuit diagram (Figure 4). The setup includes:

- 2 Wires for Positive Supply: and

- 2 Wires for Negative Supply: and

- 2 Wires for Sensor Output: and

The sensor output wires ( and ) are directly linked to the pressure level applied to the sensor. This configuration ensures high precision in both pressure and temperature measurements, making it a robust solution for demanding applications.

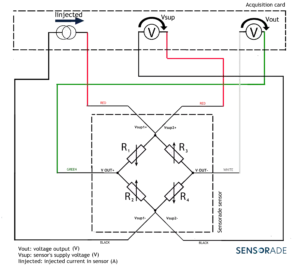

Sub-option 1: Acquisition card with a current injector

In this method, a known current is injected, and the supply voltage of the sensor is measured to calculate the resistance of the Wheatstone bridge. This resistance provides information about the temperature and enables compensation for its effects. The acquisition scheme is shown below. Two curves are provided to the user:

Temperature vs. Resistance Curve (Figure 5):

This curve illustrates the relationship between the sensor’s resistance and temperature, calculated using the formula:where:

R = Vsup * Iinjected, with R= sensor’s resistance; I= injected current; Vsup= Vsup+ – Vsup- (which is the measurement of the sensor’s voltage supply).

Pressure vs. Output Voltage Curve (Figure 6):

This curve provides pressure information based on the output voltage (Vout+ – Vout-), the sensor’s voltage supply (Vsup), and the sensor’s temperature (linked to its resistance). Each temperature level has a unique curve (Vout/Vsup, P). Therefore, the user must know the operating temperature to pre-balance the bridge at the appropriate value.

Equipment Needed: An acquisition card with a current injector.

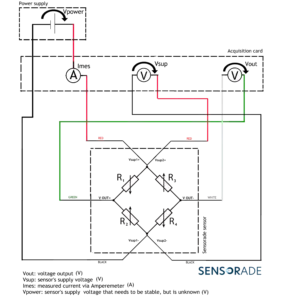

Sub-option 2: Acquisition card without a current injector but with an Amperemeter

In this method, the current injected into the sensor is measured along with the sensor’s supply voltage to calculate the resistance of the Wheatstone bridge. This resistance provides information about the temperature and enables compensation for its effects. The acquisition scheme is shown below. Two curves are provided to the user:

Temperature vs. Resistance Curve (Figure 5):

The 1st curve (Figure 5) gives information about the temperature according to the sensor’s resistance which is calculated using the formula: R= Vsup * Imeasured, with R= sensor’s resistance; I= measured current via Amperemetre; Vsup= Vsup+ – Vsup- (which is the sensor’s supply voltage).

Pressure vs. Output Voltage Curve (Figure 6):

The 2nd curve (Figure 6) gives information about the pressure according to the voltage output (Vout+ – Vout-) and the measurement of the sensor’s voltage supply (Vsup) and also according to the sensor’s temperature that’s linked to the resistance. For each temperature level the curve (Vout/Vsup, P) is different which means the user should be set on the right temperature.

Equipment Needed: An acquisition card with a current injector.

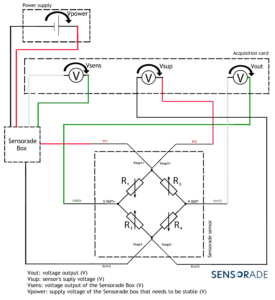

Sub-option 3: Acquisition Card without a current injector but with a Sensor Box

As an alternative to using a current injector or ammeter, a specific Sensor Box can be employed. This device connects to the acquisition card’s input and provides a voltage supply to the sensor. Its output voltage enables the determination of the current flowing through the sensor. Using this information and the supply voltage, the sensor’s resistance (Wheatstone bridge) can be calculated. This resistance provides access to temperature information and facilitates compensation for its effects. The acquisition scheme is shown below. Two curves are provided to the user:

Temperature vs. Resistance Curve (Figure 5):

The 1st curve (Figure 5) gives information about the temperature according to the sensor’s resistance which is calculated using the formula: R= f (Vsup, Vsens) = (Vsup * Isens), withR= sensor’s resistance; Vsup= Vsup+ – Vsup– (which is the measurement of the sensor’s voltage supply); Vsens= sensorade output voltage (which represents an image of the current); Isens= calculated current (formula given with the Sensor Box)

Pressure vs. Output Voltage Curve (Figure 6):

The 2nd curve (Figure 6) gives information about the pressure according to the voltage output (Vout+ – Vout-) and the measurement of the sensor’s voltage supply (Vsup) and also according to the sensor’s temperature that’s linked to the resistance. For each temperature level the curve (Vout/Vsup, P) is different which means the user should be set on the right temperature.

This specific sensor box offers the advantage of operating with an acquisition system that does not require a current injector, providing a versatile and efficient solution for temperature and pressure compensation.

Equipment needed : an acquisition card, the sensor box.

- Figure 5: Sensor's resistance according to temperature

- Figure 6: Output voltage of the sensor according to pressure

*Disclaimer: The data presented is not contractual and is directly influenced by the quality of the material used, the acquisition system, and the accuracy of the power supply source.