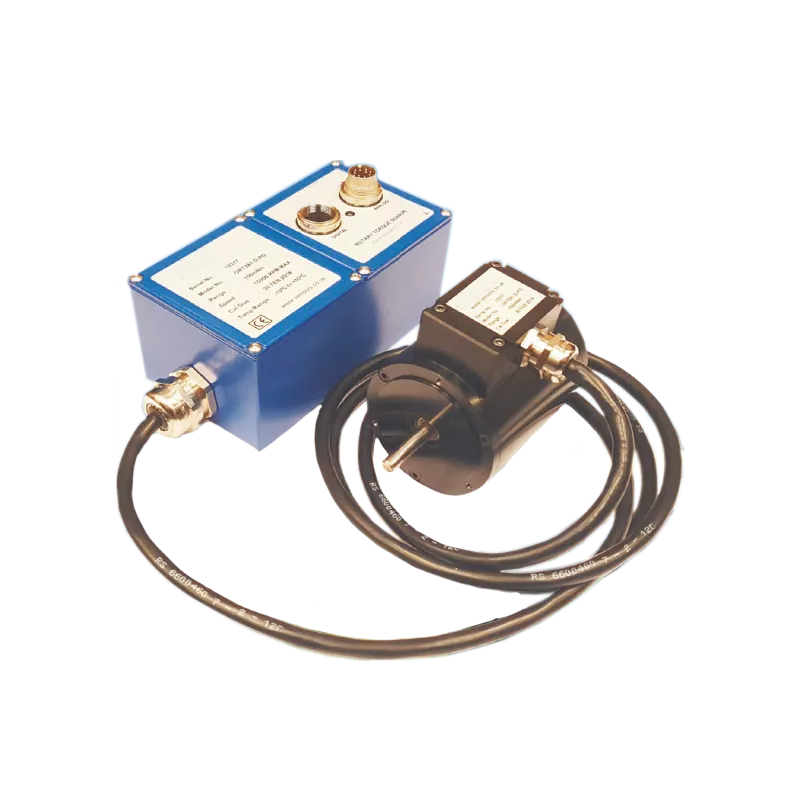

ORT 230/240 Rotating Torque Sensor

Optical torque transducer

Caractéristiques principales

- Capacity: 0,02 / 0,1 / 0,75 / 1 / 20 / 100 Nm

- Low inertia – High Speed capability because electronics are not fixed onto shaft

- Non contact/brushless measurement

- High Bandwidth

- 200% safe mechanical overload

- Excellent noise immunity

- Separate digital electronics

About the ORT 230/240 Rotating Torque Sensor

The ORT 230/240 Transducer offers an ideal means for precise dynamic measurement of rotary and static torque

less than 100 Nm and for bandwidths of up to 50 kHz. The new TorqSense ORT 230/240 torque sensors replace the E200 ORT series and feature all new electronics that have produced significant performance gains in resolution, frequency response, reduced sensor current consumption and faster digital data throughput.

Additional features ORT 230/240

- Operates both statically and dynamically

– clockwise/anti-clockwise - Any full scale torque can be specified within standard range: 10mNm through to 100Nm

- Lifetime warranty

ORT230 / TorqSense ORT230 Series transducers offer

- Fixed voltage or current analog outputs (one for torque and the other for speed or power) for interfacing with analog instrumentation

- BIT Self-diagnostics for letting the manufacturer know that the transducer’s torque, speed ratings and calibration due date have not been exceeded

- Simple ‘Sensor status’ output pin

- Sensors to monitor shaft temperature for better compensation and accuracy

ORT230 / Whereas, TorqSense ORT240 Series transducers offer

- Digital outputs, such as RS232, CANbus and USB, for interfacing with modern instrumentation and laptops

Digital input for configuring transducer via PC - 2 x user selectable voltage or current analog outputs (one for torque and the other for speed, power or peak torque) for interfacing with analog instrumentation

- Transducer configuration software to allow user to changes transducer variables

- BIT Self-diagnostics for letting users know data is trustworthy, that the transducer’s torque, speed ratings and calibration due date have not been exceeded

- Simple ‘Sensor status’ output pin

- Sensors to monitor shaft temperature for better compensation and accuracy

- Ability to connect up to 10 transducers using USB

Avez-vous besoin de ce capteur pour votre prochain projet?

Demandez un devis sans engagement ou envoyez-nous vos coordonnées pour une consultation gratuite et sans engagement. Nos ingénieurs commerciaux vous contacteront dans un délai maximum de 1 à 2 jours ouvrables.

Téléchargements de produits

Parlez à nos experts

Vous ne trouvez pas exactement ce que vous cherchez ? Nous proposons des capteurs et des systèmes de mesure standard, mais nous pouvons également vous aider à concevoir un capteur sur mesure ou une solution de mesure complète. N'hésitez pas à nous contacter pour obtenir des conseils ou un devis.

Parler à un expertSpécifications techniques

| Spécifications | Valeur |

|---|---|

| Combined non-linearity and hysteresis | ±0.5 %FS |

| Nominal voltage, vs | 12 to 32 (max) V |

| Operating range, Δto | -10 to +50 °C |

| Output | ±1 V, ±5 V, ±10 V, 4-20 mA, 0-20 mA, 12±8 mA, CAN Bus, RS232, USB |

| Power consumption, ws | 3 W |

| Repeatability | 0.1%FS |

| Resolution | 0.02%FS |

| Speed (max) | 15000 - 30000 rpm |

| Storage range, Δts | -20 to +70 °C |

| Temperature accuracy | ±1 °C |

| Torque (max) | 0.02 / 0.1 / 0.75 / 1 / 20 / 100 Nm |