Looking for a reliable measurement solution for your crane or lifting application?

Whether it's a new OEM development or an existing installation you want to optimize: we think along with you. Do you need accurate measurements, reliable data and a solution that fits your application perfectly? We offer just that. Our technical specialists translate your specifications into a well thought-out measurement system, fully tailored to your project. From sensor selection and custom configuration to cabling and data collection, we provide a complete, turnkey solution if needed. Many of our sensors are customizable to your needs. Let us know what you need, we will be happy to advise you, free of charge and without obligation.

Sensor technology applications in cranes

Safe and accurate load monitoring for mobile cranes

A mobile crane must be able to move heavy loads safely and stably, even with variable boom lengths and angles. If the permitted overturning moment is exceeded, there is a risk of overturning or structural damage. By continuously monitoring the load moment, dangerous situations can be prevented. Our sensor technology enables automatic shutdown or warning as soon as a critical value is reached. Various sensor types are used for these monitoring solutions, including: Force sensors for measuring the load on boom and lifting system. Tilt and inclinometers for exact determination of boom position. Pressure sensors for monitoring hydraulic systems.

These sensors provide reliable real-time data for integration into safety systems and machine control. Thus you increase safety, prevent damage and meet the most stringent requirements within lifting technology.

Maximum stability thanks to smart punch monitoring

For safe lifting operations, the support legs (outriggers) of mobile cranes must be fully extended and correctly positioned. Incomplete or asymmetrical extension increases the risk of instability and can lead to dangerous situations. Using sensor technology, stability is actively monitored. Linear position sensors, pressure sensors, force sensors and tilt and inclinometers check that all outriggers are correctly positioned and have sufficient load capacity before the lifting process is released. This real-time monitoring increases safety, prevents damage and supports compliance with safety requirements and standards within lifting technology.

Wind monitoring on cranes with long booms

Cranes with long booms are sensitive to wind loads. Wind gusts can cause vibrations that lead to dangerous deflections, uncontrolled load movements or even the crane falling over. Especially in large-scale construction projects on open or elevated sites, such as wind farms or high-rise buildings, this poses a significant risk.

Using tilt and inclination sensors and acceleration sensors, wind-induced vibrations can be accurately detected and analyzed. This enables timely intervention and significantly increases safety on the construction site.

-

A-Class QualityApplied in lifting technology

-

Long-term PartnershipIn product an process

-

Reliable and ExperiencedProven trackrecord over 75 years

-

Innovative and NewState-of-the-art products and developments

Product categories

Tilt measuring & switching systems

- Measuring range 0° to 360°

- Build-in sensors & EMC-safe enclosures

- Precise & low-noise analogue outputs

General purpose pressure sensors

- Measuring range -1 to 10.000 bar

- Standard Low-cost

- Variety of options available

Data acquisition (DAQ)

- Modular and scalable

- Can be integrated on of a wide range of sensor types

Inclination measurement systems

- Measuring range ±3° to ±10°

- Portable, ready to use systems

Draw-wire sensors

- Measuring range 0 to 50.000 mm

- Highly flexible steel measuring cable

- Up to 0.01 mm accuracy

Cylindrical force sensors

- Measuring range 30 N to 5 MN

- With quantified extraneous load

- Accuracy from 0.5% to 0.05%

Pancake (low profile) load cells

- Measuring range 50 to 750.000 kg

- Used for static fatigue testing

- Excellent accuracy & low body design

Our customers

Our projects

Associated products

ALF330 Load Cell

- Measuring range: ~0.5 N to ~20 N

- Excellent high resolution

- Minimal translational deflection

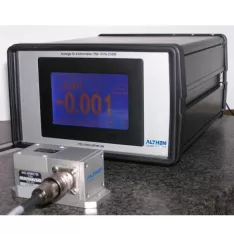

PNS Digital Display

- Measurement range ±1° to 90°, depending on inclinometer

- Power supply 24 VDC with external power supply

- Display of the inclination in Degree, %, mm/m or Grad:min:s

Load moment monitoring system (LMS) of the crane

To ensure the safety of the crane, the load and especially the crane operator and bystanders, most (mobile) cranes are equipped with a load moment safety system (LMS). This system prevents the crane from overloading or tilting during lifting. An LMS consists of several components:

- Sensors that record relevant measurement data

- A calculation unit that calculates the current load moment

- A display on which the operator can read the status and warnings in real time

- Load cells or load measuring pins for direct measurement of the weight of the load

- Pressure sensors that measure the hydraulic pressure in the cylinders

- Cable tension transducers that record the tensile force in lifting cables

- Tilt and inclinometers that detect the position of the boom

By combining this data-for example, the pressure in the lifting cylinder together with the boom angle and boom length-the system accurately calculates the current load moment. Thus, the LMS prevents the crane from exceeding a critical load, and the system intervenes when the safe limit is reached.

Permitted payload for cranes and mobile cranes

Sensors continuously measure important parameters, such as load, pressure and position. Based on this data, the control system calculates in real time both the current load and the maximum allowable lifting capacity. This information is shown directly on the crane operator's display.

When the lifting capacity approaches the maximum payload, the load moment limitation system (LMB) issues a visual or audible warning. If the limit is exceeded, the system intervenes automatically: critical functions of the crane are restricted or switched off to ensure safe movements.

For maximum safety, we use only highly accurate and reliable sensors developed specifically for applications in cranes and LMB systems.