Smart railway sleepers with multi-sensor solution

Measurement of strain, DC voltage, thermocouples and Pt-RTD

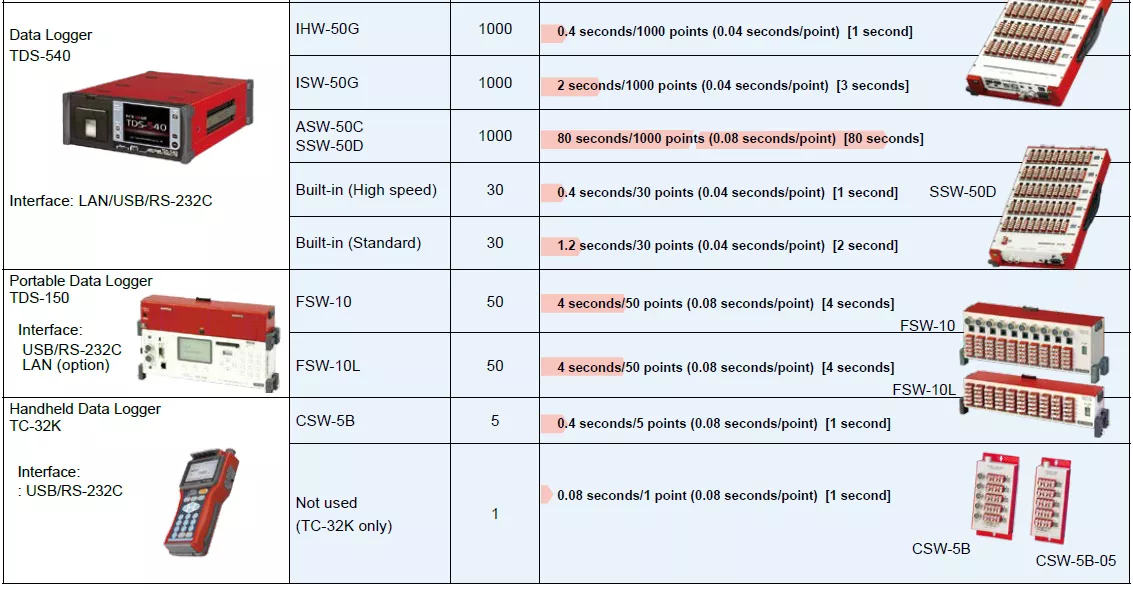

A strain that does not change over time during the measurement is called a static strain. Two or more points of static strain can be measured with a strain gauge by scanning the input channels. Each strain is output as a digital value. The automatic measurement of a large number of measuring points is possible by additionally using special switches.

We offer standard TML data loggers, but can also help you with a customised design or a complete measurement solution

Data loggers for strain measurement are used in a variety of applications, especially where it is important to monitor and record the deformation or stress of materials or structures over a period of time.

Data loggers or static strain gauges are equipped with functions for calculating, storing and processing measurement data as well as for automatically sampling several points. In addition to strain, stresses and temperatures can also be measured. The data loggers from TML allow fast measurements and complex data processing.

We have the right data loggers for every application. We are happy to support you in your selection. At Althen, we draw on more than 45 years of experience to offer you the optimum solution: tailored to your requirements. This also includes customized data loggers and measuring devices as a complete package. Do you have any questions? We are here to help you!

We offer TML data loggers but can also help you with matching strain gauges and accessories or a complete measurement solution.

Data loggers for strain measurement are specialized devices designed to continuously measure, record and monitor deformations and strains of materials, components or structures. The special features of these data loggers include

TML's strain measurement data loggers offer a range of specialized functions and features that make them particularly suitable for applications where precise and reliable acquisition of many strain measurement points simultaneously is required.