Wireless wheel load system for trams and metros

Precise and high-quality systems and tools for operation and maintenance

We offer a variety measurement solutions for the Railway industry; from sensors that can be embedded in trains, to measurement instruments for maintenance departments. Also structural health monitoring solutions are part of our scope. Where previously lots of time and labor was needed to make accurate measurements, our high-tech tools complete measurements within seconds.

We offer standard Railway measurement systems, but can also help you with a customised design or a complete measurement solution

We offer high-precision and high quality railway measurement systems. These systems contain multiple unique measurement tools related to the railway industry. Various dimensions and profiles of both rails and wheels can be measured based on state of art laser technology. Where previously lots of time and labor was needed to make accurate measurements, today the Althen high-tech tools complete measurements within seconds. The railway systems can be custom made. Please contact us - we look forward to provide you with a tailor made solution!

Increasing demands on rail transport in terms of reliability, punctuality, growing passenger numbers and shorter journey times are placing ever greater demands on measurement technology. In order to realise safety-relevant monitoring and predictive maintenance in passenger and freight transport, reliable monitoring of important system components is necessary. This requires robust and accurate sensors and measurement technology solutions. Althen offers innovative and cost-effective solutions for predictive maintenance, servicing and maintenance, quality assurance and repairs.

With us, you will find the right web measurement technology and the right web tools for every area of application. We are happy to support you in your selection. At Althen, we draw on more than 45 years of experience to offer you the optimum solution, customised to your requirements. This also includes customised web measurement systems as a complete package. The advantage for you is that we are not tied to one manufacturer and can advise you independently. On request, we can customise the measurement system exactly to your needs. Do you have any questions? We are here for you!

From simple handheld devices to fully automatic, non-contact laser systems: Althen offers you a broad portfolio of extremely precise and high-quality systems for railroad measurement technology. Using the latest laser technology, you can take a wide variety of measurements on rails and railroad wheels, for example.

All web measuring systems are fully automatic and very easy to operate. This allows you to avoid many time-consuming manual measurements. This saves you time and resources. You also speed up your maintenance and servicing processes. On request, we can adapt our web measuring systems to your individual requirements. The high-tech tools from Althen enable highly accurate measurements within seconds. In addition to permanently installed measuring tools, we offer mobile handheld devices for flexible use in various maintenance facilities and railroad systems.

Whether for high-speed traffic, local public transport or freight transportation: Althen is your reliable partner. We supply innovative and cost-effective solutions for quality monitoring and predictive maintenance of rail vehicles - both in operation and in maintenance and repair.

The rail pact poses major challenges for rail operators, infrastructure owners and vehicle maintenance companies: How can the planned growth in passenger and freight transport be implemented successfully and economically? The prerequisite for rapid improvements is reliable monitoring of important system components of infrastructure and trains in order to reduce failures and lower maintenance and repair costs. This can be achieved through the use of sensors and monitoring systems as well as their networking with databases and subsequent data analysis. Althen GmbH Mess- und Sensortechnik offers a wide range of innovative solutions for this:

Do you need advice, further information or a customized solution? We will be happy to advise you!

There are a number of risks that can lead to a train derailment. These include the failure of mechanical running gear components, displaced loads or dynamic effects of the interaction between the track and the rail vehicle. The smallest deviations in these parameters must be detected with maximum reliability so that the maintenance team can evaluate the data in good time and plan and implement any necessary repairs or maintenance work promptly.

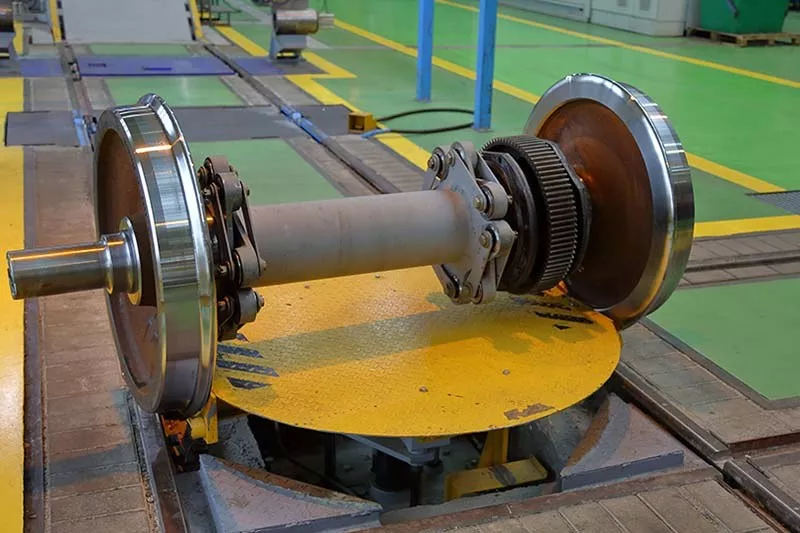

Defective wheels can cause other parts - such as the wheelset or the rails - to wear out and, in the worst case, lead to the derailment of a train. All wheels must therefore be regularly checked for possible damage and maintained. Flat spots and the lack of roundness of the wheel are among the most common signs of wear. Diagnosis can be carried out quickly and inexpensively on the open track while the train is passing. This significantly speeds up and simplifies the subsequent maintenance of the rail vehicles.

Correct weighing and weight detection play an important role in freight trains. Determining the exact weight of locomotives and wagons prevents the infrastructure from being overloaded, can form the basis for usage fees and provides safety-relevant information (for example, if the load shifts during the journey).

In addition to the monitoring of rail vehicles, the monitoring of infrastructure such as bridges, rails, switches and track beds is also an important part of a functioning rail system. While the focus is on monitoring vibrations in bridges, the track bed is examined for vibrations and changes. This information is of great importance for the maintenance and renewal of the track bed.

Wheels on railroads and streetcars are subject to continuous wear. Consequences include changes to the diameter, flange height and spacing of the wheels. In order to be able to plan maintenance and repair work on rail vehicles in good time, it is advantageous if the service team knows all the wheel parameters before the train arrives at the maintenance depot. One solution is the simple and quick measurement of the wheels by laser during the passage.

Our measuring devices for wheel maintenance provide you with reliable and accurate wheel parameters. They are based on laser technology (contactless measurements) and have been specially developed for use at railroad maintenance sites. They measure the diameter and inner distance of the wheels on an axle in a modern and innovative way and scan the profile. The software collects and stores the data of all measurements via Bluetooth. You can easily transfer the data to other systems.

We offer standard railway tools and solutions but can also help you with a customized design or a complete measurement solution.