3D Wheel Measurement System

Suited for automated contactless analysis of railway wheels

Key features

- Accurate and valuable data within seconds

- Eliminate manual measurement errors

- Integrated software system with all necessary calculations and parameters

About the 3D Wheel Measurement System

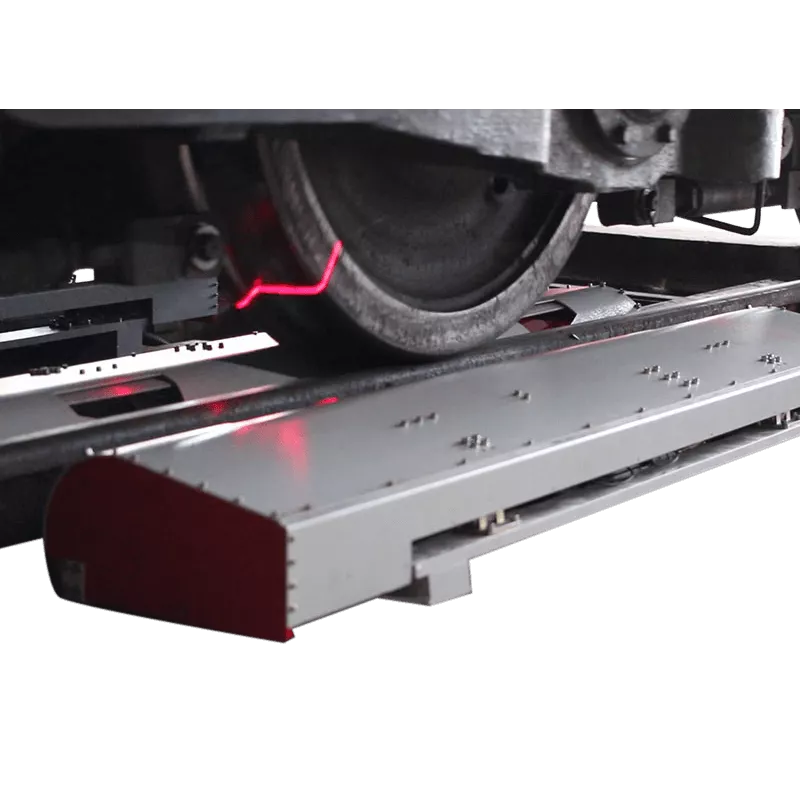

Our new 3D Wheel Measurement System is collecting reliable and accurate data to improve railway maintenance activities and to prevent damage on rail infrastructure. By making use of high speed laser scanners, it is possible to measure all wheels even at high speeds.

The system consists of 4 sensor-boxes installed on both sides of each railbeam. Just before the train passes by, the windows of the sensor-boxes open automatically letting various 2D Laser Scanners scan sections of the wheels.

All measurements are combined into a point cloud and various algorithms calculate specific parameters such as diameters, flange heights, QR, hollow wear and much more!

In order to always function to perfection a cleaning system, cooling and heating system is integrated.

Benefits of the 3D Wheel Measurement System

- Getting all important data with one system instead of multiple tools

- Accurate and valuable data within seconds

- Eliminate manual measurement errors

- Integrated software system with all necessary calculations and parameters

- Real time measurement of moving train or tram wheels

- Simple train identification based on vision system

- RFid identification of axles of the train

- Easy installation at any rail infrastructure

Measured Parameters

- Diameter of wheels

- Wheel flange height

- Wheel flange thickness

- Wheel flange slope (QR in mm or degrees)

- Wheel hollow wear (in combination with position)

- Specific slopes and angles in profile

- Gap measurement

- Complete profile of wheel as X,Y model

- Back-2-back distance between wheels on same axle

Options

The 3D Wheel Measurement System can be installed in 3 variants:

- Low speed variant for maintenance locations: up to 15 km/hour.

- Medium speed variant for normal train/metro trajectory: up to 180 km/hour.

- High speed variant for in high speed trajectory locations: up to 350 km/hour.

Do you need this sensor for your next project?

Request a no-obligation quote or send us your contact details for a free, no-obligation consultation. Our sales engineers will then contact you within a maximum of 1 to 2 working days.

Talk to our experts

Not exactly what you are looking for? We offer standard sensors, but can also help you with sensors adapted for you or a fully customised measurement solution. Contact us for advice or pricing.

Talk to an expertTechnical Specifications

| Specification | Value |

|---|---|

| Back-to-back gauge (accuracy) | ± 0.05mm |

| Flange angle (accuracy) | ± 0.1mm |

| Flange height (accuracy) | ± 0.1mm |

| Flange width (accuracy) | ± 0.1mm |

| Rim thickness (accuracy) | ± 0.1mm |

| Thread width (accuracy) | ± 0.1mm |

| Wheel diameter (accuracy) | ± 0.2mm |

| Wheel profiles (accuracy) | ± 0.1mm |