While condition monitoring instruments are often already integrated into newer industrial production systems, it is often more difficult to retrofit existing systems with measurement solutions that allow for predictive maintenance. For existing systems, primarily with rotating system components - such as motors, gearboxes, pumps or fans - measurement specialist Althen offers a condition monitoring system that is easy to retrofit using vibration measurement. Wireless measurement nodes communicate the measurement data wirelessly to a gateway, which then transmits it to a cloud. Althen has developed a monitoring solution for data analysis that offers a wide range of clear evaluation options.

Simple and complete IoT solution

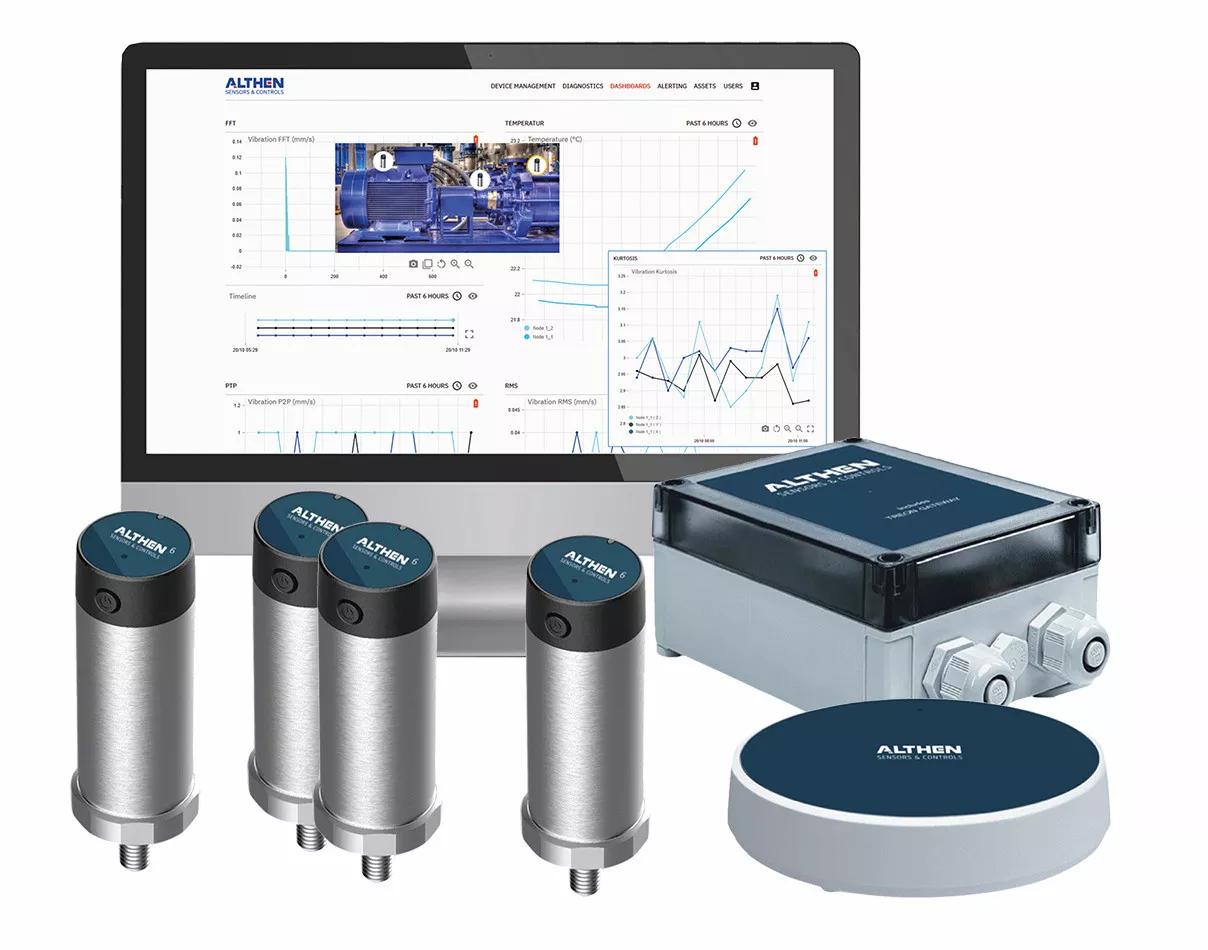

Machines with rotating system parts are subject to greater wear due to the resulting oscillations and vibrations. Predictive condition monitoring is crucial here in order to detect wear at an early stage, prevent failure and ultimately save costs if wear parts can be serviced in good time and replaced as planned. Measurement specialist Althen offers a measurement solution for vibration measurement and condition monitoring consisting of wireless, battery-operated vibration sensors that transmit the measurement data to a cloud via gateways, as well as the "Althen Monitor" for data evaluation.

Measuring nodes, gateway and mesh network

These measuring nodes measure vibrations in three directions and process these signals in the sensor itself. Vibration measurements usually generate a lot of raw data, which requires a large volume of data to be transmitted wirelessly. However, the vibration sensor from Althen does not transmit the raw data unfiltered; instead, it is possible to specify in advance which vibration acceleration data is to be processed and transmitted. The data is passed on via a self-organising mesh network consisting of several measuring nodes that communicate with each other and with the gateways used. Depending on the system situation and available space, one gateway is responsible for radio communication for up to 25 sensors. The network can be expanded or reduced by adding measuring nodes and gateways at any time, depending on requirements. The wireless vibration sensors are also available in an ATEX-certified version for use in potentially explosive atmospheres.

Monitor solution with versatile dashboard

The special feature of the monitoring solution is the dashboard developed by Althen, which can be used to analyse the collected data in a variety of ways and thus provide information about the condition of the system and possible maintenance intervals. The structure of the dashboard can be customised to the customer, e.g. at system, building or site level, or even across companies and countries. Alarm messages are sent by email when the desired limit values are defined. The IoT monitor offers the option of limit value monitoring as well as the measurement of individual machine data. Depending on the scope the measurement solution includes the basic and more detailed diagnostic functions.

The impact of IoT projects

Study Internet of Things (2022)

-

Optimisation of existing business processes44 %

of the companies were able to optimise their existing business processes with the help of IoT projects.

-

Generating added value90 %

of the companies are very satisfied to somewhat satisfied with the results of their IoT projects to date.

-

Quality control50 %

Quality control is the most important IoT application at 50%, followed by networked production at 34%.