The SENSOR+TEST in Nuremberg is the world's leading forum for sensor, measuring and testing technology - an indispensable meeting place for industry experts, developers and users.

We from Althen Sensors & Controls will be there again this year to present our latest solutions and product innovations. Take the opportunity to talk to our experts on site and discuss customised solutions for your specific applications. Experience first-hand the concentrated expertise and exciting developments in the field of sensor technology. In the accompanying forums, you can deepen your specialist knowledge and experience technological trends at first hand.

Visit us at the SENSOR+TEST and be inspired by our expertise. Together we will find the optimum solution for your requirements - because your success is what drives us. It's worth it!

You will find ATLHEN Sensors & Controls in Hall 1 - 230.

Event details

Location: Exhibition Centre Nuremberg, Stand 1-230

Date: 8 - 6 May 2025

Opening hours: Daily 9 a.m. - 5 p.m.

Free exhibition ticket

Once again this year, we are offering you the opportunity to visit the trade fair free of charge. Simply register via the following link and you will receive a free e-ticket for your visit to the trade fair.

Meet our experts

Whether you need product information or project advice - we are there to help! Arrange your personal appointment now at our trade fair stand and meet our experts on site in Nuremberg.

Forum presentation

Radio-based IIoT condition monitoring: easy retrofitting of machines and systems

Date: Wednesday, 7 May 2025

Location: Hall 2 | Time: 11:30 - 12:00

Speaker: Stefan Kunisch

Existing systems often lack integrated monitoring tools, which makes predictive maintenance more difficult. According to TÜV Rheinland, 30-35% of damage could be avoided with a condition monitoring system. Measurement specialist Althen offers a retrofittable, wireless monitoring system for rotating plant components. Sensors send vibration data wirelessly to a gateway and on to the cloud. The Althen software enables detailed analyses from threshold value triggers to FFT diagnostics. Users can create individual dashboards and visualise production lines. The presentation will cover the use of sensors, installation and functions of the Althen IoT Monitor.

Product Highlights

Geotechnical measurements

Geotechnical inclinometers are precise measuring devices that are used to monitor ground movements and deformations in buildings and geostructures. They are used to recognise potential dangers such as landslides, foundation failure or subsidence at an early stage. In safety monitoring, they identify movements that could jeopardise buildings or people. The sensors can be used to support construction planning and the validation of ground stability models. They are also suitable for long-term monitoring, e.g. to check soil behaviour after the completion of construction projects (such as in mining or dams).

JMHI-100/200 Ruby MEMS Inclinometer

- Seal: IP67

- M12 and DB9 termination options

- RoHS compliant

500 Self-Leveling Borehole Tiltmeter (Lily)

- Resolution up to 5 nanoradians

- For depths to 3500 meters.

- RS-232 or RS-422 Output

Soil pressure measurement

Increased earth pressure can indicate an unstable soil structure or impending ground movements that could lead to landslides, landslides or other dangerous situations. By continuously monitoring this pressure, potential risks can be recognised at an early stage so that protective measures can be taken in good time to prevent damage and accidents. Model tests are often carried out before the start of construction projects. Althen offers various ground pressure sensors from TML for this purpose.

KDA-PA/KDB-PA Soil Pressure Gauge

- 200 mm in outside diameter

- Double diaphragm structure

- Measures dynamic earth pressure, too

KDJ-PA/KDK-PA Load Cell type Soil Pressure Gauge

- Made of all stainless steel

- Excellent corrosion resistance

- Robuster than the diaphragm type

KDE-PA/KDF-PA Soil Pressure Gauge

- made of all stainless steel

- 50 mm inoutside diameter

- dual-diaphragm structure

Condition Monitoring

Strain gauges for condition monitoring are specially developed sensors that are used to measure deformations and stresses in concrete structures or synthetic resin. Among other things, these sensors measure the stress and temperature of the material during curing (internal strain measurement) as well as the behaviour of cracks in the surfaces of the materials. They are required for roads, bridges, retaining walls, struts and sheet piling.

KM strain transducer

- Measurement of curing in materials such as concrete + synthetic resin

- Self temperature compensated strain gauge

- Simultaneous measurement of strain and temperature

KG-A Crack displacement transducer

- Drip-proof structure

- Excellent stability over a long priod of time

- High sensitivity, High accuracy

Condition Monitoring

The wireless vibration monitoring system from Althen makes it easy to retrofit rotating machinery such as motors, pumps and compressors - without any additional hardware. The system comprises battery-powered, wireless industrial sensors and a gateway that securely transmits the recorded data to the cloud. A flexible dashboard is available for analysis and visualisation, which can be tailored to your specific requirements.

Wireless Iot Vibration Industrial Sensor Node 6

- Frequency range up to 6.3kHz

- ATEX, IECEx and Microsoft Azure certfications

- Operating temperature range -40°C to +85 °C

Wireless Ambient Sensor Node

- Measures movements and vibrations

- Integrated HAL-sensor

- Battery CR2477, 1000 mAh

Industrial IoT Gateway

- Can connect to hundreds of sensor nodes

- Supports wired and wireless connectivity

- Stylish in design and compact in size

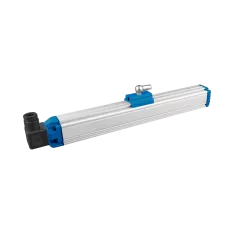

Magnetostrictive linear position sensors

Our magnetostrictive linear position sensors offer a precise and reliable way to monitor the position of moving parts in various applications. They measure according to the magnetostrictive principle and - due to the non-contact measuring method - are suitable for environments in which dust, dirt or vibrations can impair an accurate measurement. They are used wherever high accuracy and long-term stability are required.

MSS Contactless Magnetostrictive Position Sensor

- Measuring range 50 - 5000 mm

- 16 bit resolution

- Repeatability ±0,005% (full scale)

MSW Magnetostrictive Linear Position Sensor

- Measuring range 50 mm to 5.000 mm

- 16 bit resolution

- Wear- and maintenance-free

MST Magnetostrictive Position Sensor

- Measuring range 100 mm to 900 mm

- 16 bit resolution (200 µm)

- Wear- and maintenance-free

Impressions Sensor + Test 2024