The process control system (PCS) acts as the central control and monitoring unit in the company. Various processes and systems throughout the company or in a specific plant are monitored and controlled from here. To ensure a clear control room, it is therefore advantageous if a separate monitoring solution is not required for each system or monitoring. Althen's condition monitoring system offers a flexible solution here, as it can be seamlessly integrated into various external or third-party systems.

Althen uses the extensive possibilities of MQTT/MQTTs and HTTPS protocols, which offer a smooth connection to process control systems from various manufacturers such as Siemens, Yokogawa, Emerson and ABB.

About the communication protocols

MQTT (Message Queuing Telemetry Transport) is an open protocol developed for the transmission of messages between devices in a network. It was specially designed for communication in environments with limited bandwidth and/or unstable network connections.

MQTTs is a variant of MQTT that offers security through the use of TLS/SSL (Transport Layer Security/Secure Sockets Layer) for the encryption of communication. This protects the transmitted data from unauthorized access. In this way, MQTT and MQTTs enable reliable and secure communication between different devices and systems in a network. The MQTT client establishes a connection with the MQTT server and can then either publish messages, subscribe to specific messages or do both at the same time. As soon as the MQTT/MQTTs server receives a message, it forwards it to the relevant subscribers.

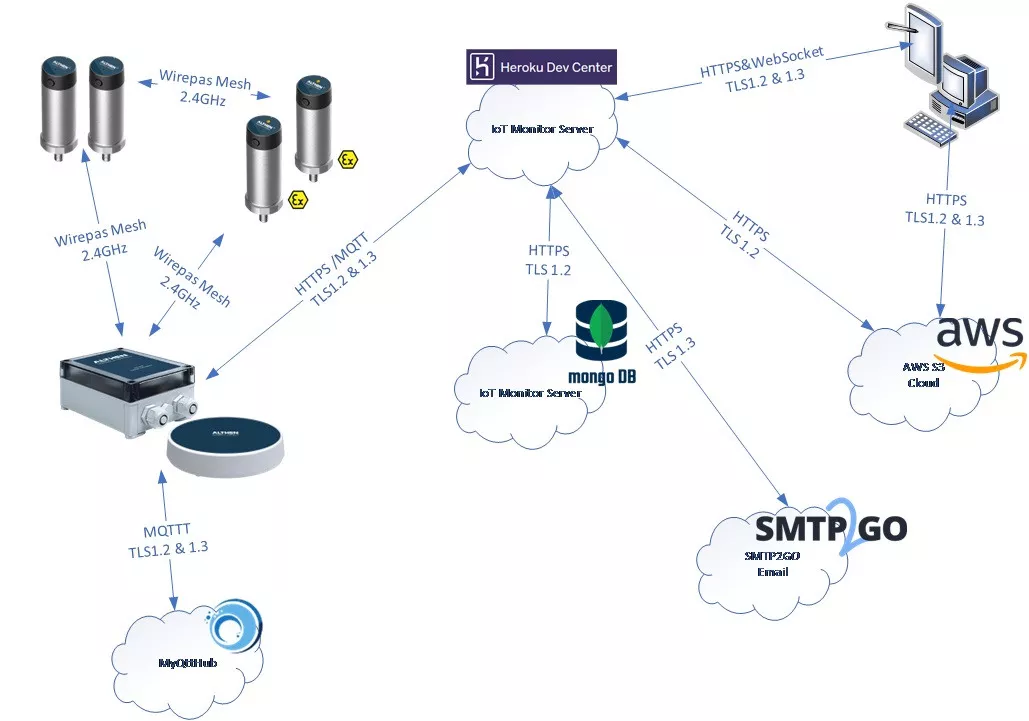

(Graphic on the right: exemplary Clould connection with the Althen IoT Monitor)

HTTPS (Hypertext Transfer Protocol Secure) is a secure version of the HTTP protocol used for transferring data on the Internet. This is the process by which data is sent from a client to a server via HTTP requests and returned to the client by the server via HTTP responses. The data is protected by encryption. It is also possible to carry out configurations remotely. In general, the manufacturers of process control systems support these protocols. Alternatively, Althen offers the use of its own cloud solution "Althen IoT Monitor".

Advantages of protocol support

In addition to the seamless integration of different systems and devices, regardless of manufacturer or platform, the scalable protocols offer even more advantages:

- Since MQTT/MQTTs and HTTPS are widely used and standardized protocols, they can be supported by a variety of systems and devices, which improves compatibility between different components and systems.

- MQTT/MQTTs and HTTPS are scalable communication protocols that are suitable for both small applications and large, complex systems. This makes it easier to handle growing requirements and increasing data volumes in the future.

- Due to their efficiency, MQTT/MQTTs and HTTPS are particularly well suited for use in environments with limited bandwidth or resources, which is the case in many industrial and IoT applications.

- HTTPS in particular offers secure transmission of data over the internet through the use of encryption technologies such as TLS/SSL. This protects the data from unauthorized access and ensures the integrity of the communication.

Why condition monitoring?

Condition monitoring is an important part of predictive maintenance - integrating a condition monitoring system, such as the intelligent, industrial IoT measurement solution for vibration monitoring from Althen, into a process control system therefore offers a number of advantages:

- Early fault detection: intelligent, continuous monitoring of plant and machinery using Althen's measurement solution means that potential problems can be detected at an early stage, even before they lead to serious failures. As a result, preventive maintenance measures can be initiated in good time and expensive downtimes avoided.

- Optimization of plant availability: Althen's effective condition monitoring system enables better planning of maintenance work, which in turn increases plant availability and reliability. Unplanned downtimes can be minimized by detecting and rectifying problems in good time.

- Increased plant efficiency: The continuous monitoring of operating parameters by the Althen condition monitoring system allows faults and inefficient operating states to be identified. This makes it possible to optimize operating processes and reduce energy consumption, which can lead to cost savings.

- Improving safety: Althen's condition monitoring system can help to identify and minimize potential safety risks at an early stage. By monitoring critical operating parameters, dangerous situations can be avoided and the safety of employees and systems can be improved.