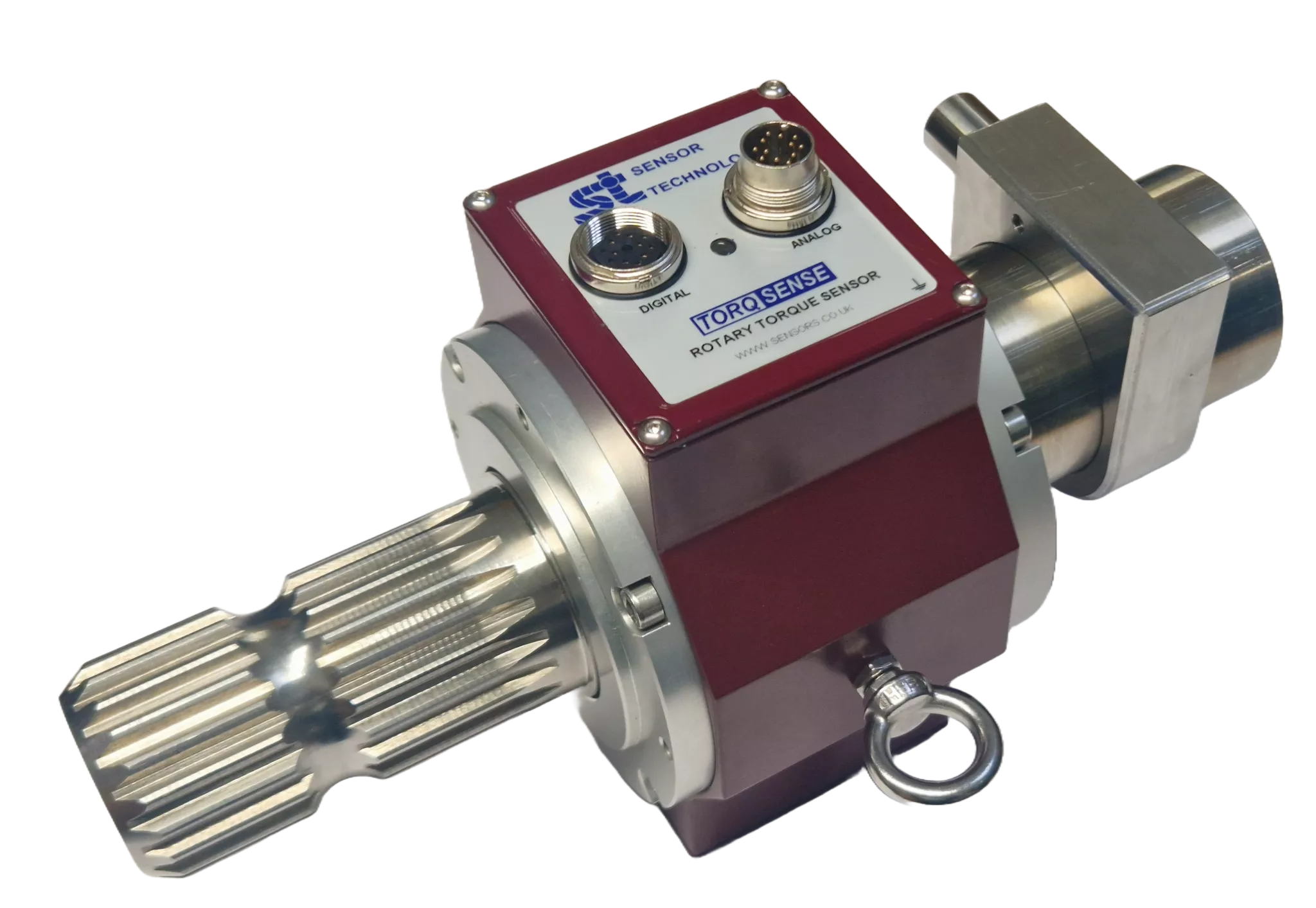

SGR570 PTO Torque Transducer

Precise and reliable torque measurement for agriculture, construction and industry

Belangrijkste kenmerken

- Transducers up to 2000Nm

- Wide power supply range 12-32 VDC

- Speed measurement / Power computation

- Adjustable torque data smoothness, low pass filter

- High digital sample rate of 4000 samples per second

About the PTO Torque Transducer

TorqView is an easy to use advanced torque monitoring software, available to assist data recording and instrumentation displays that interface with Windows based PCs. Features include: 3 types of display, text files compatible with Matlab and Excel and Real time chart plotting. See TorqView datasheet for more details. LabView VI's are available for users to design their own process control applications. DLLs are also available for users to write their own custom software. Get data from across your network using the ethernet module.

Precise and reliable torque measurement for agriculture, construction and industry: These innovative sensors provide precise torque data for power take-off shafts (PTO) and are ideal for applications in agriculture, construction and industry.

The SGR570 TorqSense was developed to meet the increasing demand for precise performance data from heavy machinery. The sensors enable optimised monitoring of PTO performance, contributing to operational efficiency and equipment longevity.

Key features

- Transducers up to 2000Nm

- Wide power supply range 12-32 VDC

- Speed measurement / Power computation

- Adjustable torque data smoothness, low pass filter

- High digital sample rate of 4000 samples per second

- Non contact signal transmission, no slip rings to wear out

- Zero variation in torque signal with rotation (cyclic variation)

- Low hysteresis error of ± 0.05 % FSD

- Low linearity deviation of ± 0.05 % FSD

- Minimal side and end load errors

- Large fully functional overrange capability of 250%

- Compatible with ethernet gateway module

Technology

The SGR series torque transducers use a full four element strain gauge bridge to measure the torsion present on a shaft. The full bridge helps to diminish errors from any off-axis forces that are sometimes unintentionally applied to the transducer in some test setups. The full bridge also increases the sensitivity

and the temperature performance of strain measurement.

A rotor mounted ultra-miniature microcontroller measures the strain gauge bridge and transfers the information back to the stator digitally eliminating any noise pickup usually associated with slip ring and other analog methods of transferring torque data from rotor to stator. External noise pickup into the gauge wiring is virtually eliminated due to the short distance between the strain gauge elements and the rotors measuring circuits.

A multipoint calibration method reduces any linearity errors within the sensor. A large functional overrange capability allows the peaks of a torque signal to be captured more faithfully without any clipping when operating the sensor close to its full scale rating. All this combined with a mechanical overload capability of over 400% make the SGR series torque sensors a very robust and

accurate torque measuring solution.

Heeft u deze sensor nodig voor uw project?

Vraag een vrijblijvende offerte aan of stuur ons uw contactgegevens voor een gratis en vrijblijvend gesprek. Onze sales engineers nemen dan binnen maximaal 1 tot 2 werkdagen contact met u op.

Product downloaden

Praat met onze experts

Niet precies wat u zoekt? Wij bieden standaard sensoren, maar kunnen u ook helpen met voor u aangepaste sensoren of een volledig op maat gemaakte meetoplossing. Neem contact met ons op voor advies of prijzen.

Praat met een expertTechnische specificaties

| Specificaties | Waarde |

|---|---|

| Measurement method | Full bridge strain gauge |

| Torque range | Up to 2000Nm |

| Shaft type | Male 1 3/8” 6 spline to female 1 3/8” 6 spline ISO500-3 Type 1 |

| Combined non-linearity and hysteresis (%FS) | ±0.1 |

| Resolution (%FS) | 0.01 |

| Repeatability (%FS) | 0.05 |

| Accuracy (%FS) | ±0.2 |