Ensuring reliability of critical components

A southern European railway operator faced recurring challenges in ensuring the reliability of critical components such as wheelset bearings and brake systems. These components are subject to significant stresses, including high dynamic loads, friction, and heat, which can lead to wear, overheating, and ultimately failure if not monitored effectively. Failure in these systems not only lead to costly repairs and downtime but also posed serious safety risks.

Key requirements for the solution included:

- High sensitivity to detect early signs of bearing wear or brake system issues.

- Durability to withstand harsh operating conditions, including vibration, temperature extremes, and contaminants.

- Real-time monitoring capability to enable early intervention and maintenance.

- Seamless integration with existing monitoring and diagnostic systems.

Wheelset bearing and brake system

To address these challenges, eventually our some of the ASC accelerometers were selected for their proven performance in precision monitoring and harsh environments. The ASC 5511LN and ASC 5525LN capacitive accelerometers were selected for wheelset bearing monitoring due to their high sensitivity and rugged design. For brake system diagnostics, we identified the ASC 5515LN acceleration sensors as the ideal solution, thanks to its capability to measure low-frequency vibrations and its durability under high-stress conditions.

Installation of the sensors

For wheelset bearings, our ASC 5511LN and ASC 5525LN accelerometers were installed directly on the bearing housings to monitor vibration patterns. Changes in vibration signatures were used to detect early signs of wear, misalignment, or overheating. For brake systems, the ASC 5515LN accelerometer was deployed to measure vibrations during braking events, providing insights into the performance and condition of brake pads and discs. Key features of these ASC accelerometers included:

-

High accuracyDetecting subtle changes in vibration that indicate early-stage issues.

-

Rugged constructionEnsuring reliable operation in challenging railway environments.

-

Wide frequency rangeCapturing both low- and high-frequency vibrations critical to diagnosing bearing and brake system health.

-

Low noiseProviding clean data for accurate diagnostics.

Pilot period of the project

The project began with a pilot phase to evaluate the performance of the ASC 5511LN, ASC 5525LN, and ASC 5515LN accelerometers under real-world railway conditions. The pilot involved equipping a small fleet of 4 trains operating across diverse routes with sensors installed on both wheelset bearings and brake assemblies. Over a period of six months, the accelerometers collected real-time data on vibration patterns during various operational scenarios, including high-speed runs, braking events, and challenging environmental conditions. Maintenance teams analyzed this data to establish baseline metrics, detect anomalies, and refine fault thresholds. The insights gained during this phase validated the sensors’ ability to identify early signs of bearing wear and brake system issues, while ensuring seamless integration with existing diagnostic systems. During the pilot phase, real-time data was collected and analyzed using advanced diagnostic software. Engineers collaborated with us to optimize sensor placement and data acquisition settings.

After the successful pilot, the railway operator expanded the deployment of ASC accelerometers across some other models in its fleet. The implementation involved:

- Sensor placement: mounting ASC 5511LN and ASC 5525LN accelerometers on wheelset bearing housings and ASC 5515LN accelerometers on brake assemblies.

- Data integration: connecting sensors to onboard monitoring systems for continuous real-time data analysis.

- Maintenance workflow integration: training maintenance teams to interpret data and use it for predictive maintenance planning.

Implementation

After the successful pilot, the railway operator expanded the deployment of ASC accelerometers across some other models in its fleet. The implementation involved:

- Sensor placement: mounting ASC 5511LN and ASC 5525LN accelerometers on wheelset bearing housings and ASC 5515LN accelerometers on brake assemblies.

- Data integration: connecting sensors to onboard monitoring systems for continuous real-time data analysis.

- Maintenance workflow integration: training maintenance teams to interpret data and use it for predictive maintenance planning.

Accelerometers

Related acceleration sensors to this project

ASC 5511 LN / 5515 LN MEMS Capacitive accelerometers

- MEMS Capacitive

- Measurement Range: ±2 to ±400 g

- Noise Density: 7 to 400 µg/√Hz

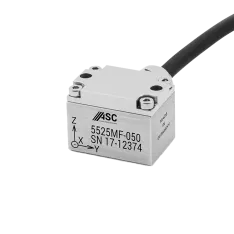

ASC 5525 MF Low-frequency accelerometer

- Low noise: from 10 µg/√Hz

- DC to 2900 Hz response

- IP67 with rugged housing

ASC 5421MF Triaxial MEMS acceleration sensor

- Medium frequency triaxial MEMS accelerometer

- Bandwidth up to 7 kHz and shock up to 6,000 g

- Aluminum or stainless steel IP65 housing

Results and impact

The deployment of ASC accelerometers for wheelset bearing monitoring and brake testing delivered measurable improvements:

- Early fault detection: The ASC 5511LN and ASC 5525LN accelerometers identified bearing wear and misalignment, while the ASC 5515LN detected brake system anomalies before they led to failure, reducing unscheduled maintenance and enhancing safety.

- Prolonged component lifespan: Timely interventions based on vibration data extended the service life of wheelset bearings and brake components.

- Enhanced safety: Continuous monitoring minimized the risk of catastrophic failures, ensuring passenger and cargo safety.

- Reduced maintenance costs: Predictive maintenance based on sensor data significantly lowered repair and replacement expenses.

- Regulatory compliance: Detailed vibration data supported compliance with safety and operational standards.

Vital tools for monitoring

The selected accelerometers, specifically the ASC 5511LN, ASC 5525LN, and ASC 5515LN, have proven to be vital tools for monitoring critical railway components such as wheelset bearings and brake systems. By enabling early detection of potential issues, these sensors have improved safety, reduced costs, and enhanced operational efficiency. Our project highlights the transformative potential of advanced sensor technology in railway applications, setting new benchmarks for reliability and performance.

ASC and Althen are partners to provide high quality sensor solutions for the railway industry.