Platform with a grid of Force Sensors

The torque created by his jump brings the jumper into the right attitude for flight. His center of gravity shifts forward above the skis, his legs are fully stretched: Now he is airborne. On average, only one in every 100 jumps has a perfect launch. The approach, launching energy, and torque combine to determine the range. Every tiny movement of the jumper can decide between victory and defeat. This is why Peter Riedel, former ski jumper and specialist for sports equipment, has worked together hand-in-glove with Althen to develop a measurement system that analyzes which forces are at work at the end of the platform.

I had the idea to fit the platform with a tight grid of force sensors in order to get a continues measurement throughout the entire jump-off. Althen proved to be a highly competent and reliable expert and implemented my ideas excellently.

Dynamometric measurements on ski jumping hills

The Force Sensors are mounted directly underneath the run-up track to record every detail of each athlete’s jump-off. We used the AU Single Point Load Cell as a force sensor. These cells are typically used in industrial applications to measure fill levels. For the ski jumping hill, we developed modules that cover the entire stretch from the run-up to the jump-off platform. A unique challenge was posed by the length of the athletes’ skis: they are three meters (almost ten feet) long. However, the force needs to be measured at the exact location of the athlete’s leg. Our system is sensitive enough to master this challenge and still deliver reliable results. Today, our technology is used on ski jumping hills around the globe, helping the world’s best ski jumpers improve their performance.

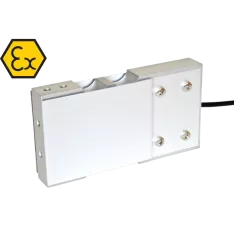

AU Single-point load cell for platforms 250x400/400x600 mm

- Capacity from 3 to 50 kg

- IP65 protection rating

- Compact, OIML certified design

AF Single point load cell

- Stainless steel housing

- Combined error ≤ ±0.05%

- IP65 protection class

ALL Single point load cell

- Measuring ranges: 0 - 3 to 0 - 50 kg

- -35°C to +65°C Operating temperature

- Aluminium alloy construction