Meulestedebrug in Ghent

The Meulestede Bridge, a major arterial road north of Ghent, is currently undergoing a major transformation. The current movable bridge over the Ghent-Terneuzen Canal, which has been heavily used by both road and water traffic for 65 years, is currently one of the few connecting points between the R4-West and the R4-East. However, the bridge has aged considerably and is about to be retired. Therefore, with a view to future safety and reliability, it was decided to replace it with a brand new bascule bridge.

About Vandezande

Vandezande is a renowned Belgian company specialising in screw pumps & hydropower jacks, water treatment plants and electromechanical equipment of bridges, locks and weirs. With almost 100 years of experience, the company provides high-quality products and services that meet the highest standards of precision and reliability.

Balance counterweight and bridge

The new design is a variant of the bascule bridge, in which the counterweight of the movable bridge is located under the fixed abutment bridge on the right over. As a result, the movable part of the bridge therefore ‘rests’ on the counterweight, and is hidden from view, allowing for an open and modern design. To properly balance the counterweight and the bridge, Althen Sensors & Controls was approached to provide a solution that would not only meet the requirements of accurate weighing, but also ensure the durability of the bridge.

Measurement and weighing technology

With years of experience in measurement and weighing technologies, Althen worked with Vandezande, an established name in Belgian hydraulic engineering, to develop a unique set of CBL and CBLS load cells. The set of load cells can determine the weight of each bridge deck, some 340 tonnes each, to an accuracy of 0.10%. The residual weight of the bridge which rests opposite the counterweight on the quay, can even be determined with 0.03% accuracy, ensuring that the bridge can be opened with minimal effort.

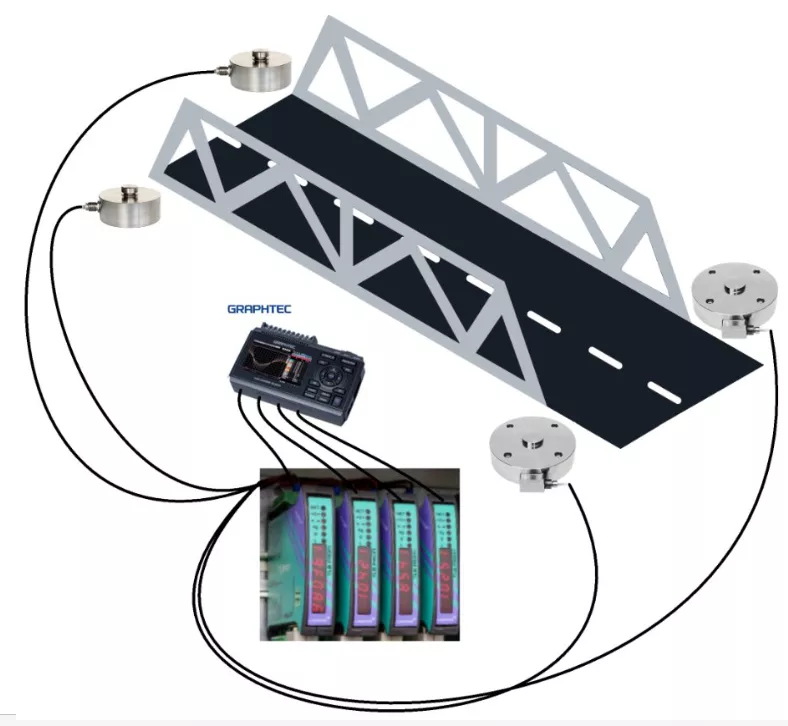

Load cells combined with live measurement and logging

The heart of this technology lies in its ability to take accurate weight measurements in real-time. The Meulestede Bridge deck, which is subject to constantly changing loads during counterweight filling, required a system that could provide immediate feedback to engineers and maintenance staff. The CBL and CBLS load cells, combined with a live measurement and logging system, provide this functionality, allowing any imbalances or excessive loads to be identified and addressed immediately.

Weighing sensors

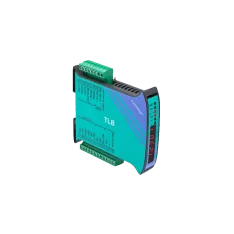

CBL and CBLS are compression-low profile load cells, which means that their mechanical structure is greater in width than in height. Also for the very high capacity version, the reduced thickness of these weight sensors makes for practical integration under the structure. The TLB weight transmitter, thanks to its transmission speed, enables immediately identifying and promptly overcoming any imbalance or excessive loads on the bridge. The high accuracy of the load cells and the installation of a single weight transmitter for each sensor ensure the precision of the process of weighing and monitoring. The easy installation of the components and the technology of the system have increased the efficiency and speed of the bridge construction process, cutting downtime to a minimum.

Related products

Sensors used for this project

CBL Pancake (Low profile) Load Cell (ATEX)

- Range: 250 to 100000 kg

- 17-4 PH stainless steel construction

- Combined error < +/- 0.03%

CBLS Pancake (Low profile) Load Cell (ATEX)

- Range: 200000 to 750000kg

- 17-4 PH stainless steel construction

- Combined error < +/- 0.10%

TLB Digital Amplifier

- Six-digit semialphanumeric display (height 8 mm), 7 segment LED

- Four buttons

- Dimensions: 25 x 115 x 120 mm

Seamless integration

What makes this project even more impressive is the seamless integration of the load cells into the bridge design. With minimal disruption to the construction schedule and a streamlined installation procedure, the CBL and CBLS load cells were an indispensable addition to the project. The use of this advanced technology contributed not only to the accuracy of the weighing process, but also to the overall efficiency of the bridge construction.

Share your challenge

We are curious about your project and measurement challenge

Please contact us for more information about your project or the sensors.