Use of intelligent test & measurement applications

IDC analysts see a tenfold increase in global data to 163 zetabytes (163 million exabytes) by 2025. About 60 per cent of this data is generated by companies. While the conversion from analogue to digital data was still in the foreground in the last decade, the industry is now increasingly focusing on the added value of this data. However, the fact that the market research company Gartner does not identify a market leader in its current Magic Quadrant, only innovators (PTC, Hitachi, SAP) and various niche providers, shows the potential for manufacturers and manufacturer cooperations. Companies, on the other hand, must now carry out a precise inventory and needs analysis and look for solutions that already offer them added value in certain application areas. The use of intelligent test and measurement applications is therefore a significant area of application for many IIoT applications.

Challenges for test and measurement applications

The general goal is to increase operational effectiveness, implement flexible production techniques and optimise data acquisition and processing processes. Sensors and sensor data play a central role in many application areas, providing the data basis for automation and self-learning machines. Predictive maintenance is also an important topic here. Structures and systems in test and measurement applications are changing rapidly, however, and corresponding data acquisition systems must be able to keep pace with these developments so as not to prove to be an investment dead end.

At the same time, there is no IIoT without analytics. In order to be able to work faster and more efficiently, data must be monitored in real time, which can quickly lead to a data collection of gigantic proportions that can hardly be processed effectively or even economically transferred to a remote server and stored. The challenge is therefore not only to collect the data, but to reduce the raw data sensibly at the point of origin in order to transfer only the relevant information and thus limit the volume of data. Data processing must also meet the high demands of performance, scalability and security. Increased efficiency in processing therefore also includes measures for indexing and grouping data, such as automated labelling (metadata, classification of data records) or statistical data reduction (mean value, standard deviation, minimum, maximum).

IIoT collaboration in the sensor environment

While the global players are still wrestling with practicable solutions, the established companies Gantner Instruments GmbH and Kelkheim-based Althen GmbH Mess- und Sensortechnik are already presenting concrete IIoT solutions for industrial measurement and testing technology. As a specialist for decentralised measurement and I/O systems as well as the measurement of mechanical, thermal and electrical variables, Gantner Instruments contributes its data acquisition and connectivity solutions as well as remote configuration and evaluation software. Althen integrates its high-quality sensors into the complete systems and takes over the customer-specific presettings of the measuring ranges, the setting of adjustment parameters for calibrated sensors as well as possible mathematical calculations and alarm settings according to customer requirements. This results in a wide range of possible applications, such as monitoring material fatigue in nuclear power plants and nuclear fusion plants, quality inspection of the track network in local public transport, strain measurement on flexible pipeline systems, predictive maintenance of machines, plants or even in mobile equipment, such as in construction machinery and railways.

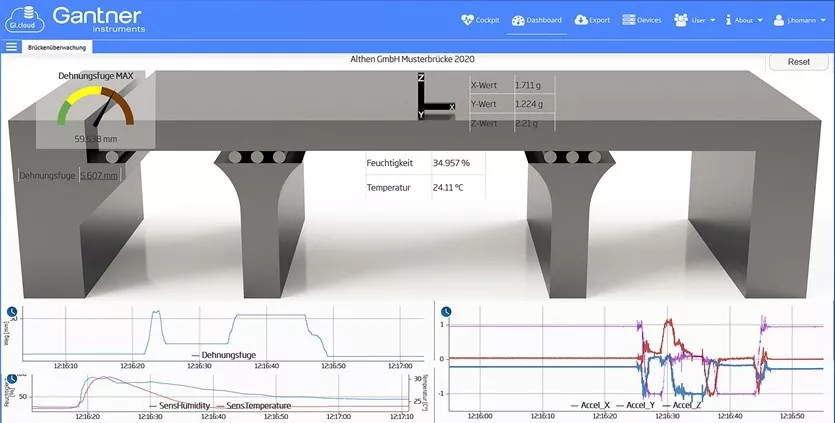

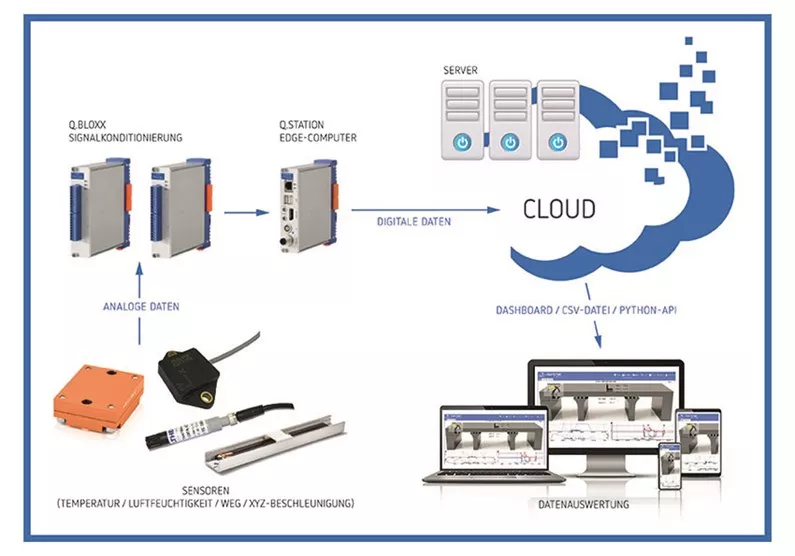

Remote monitoring of a bridge

It is worth looking at a concrete example, here the monitoring of a bridge. With a similar topology, however, further monitoring in the infrastructure sector would also be conceivable, for example for railway, road and motorway bridges, important buildings, dams, dikes or industrial plants (refineries, chemicals, wind turbines, etc.). The Q.series X from Gantner is used, a decentralised, highly flexible measuring system in modular design, which is also suitable for DIN rail mounting. This typical design of a decentralised measuring system offers a maximum of flexibility and interfaces. The arbitrary combination of data acquisition modules allows optimal adaptation to the task at hand and is ideally suited for decentralised applications. Specifically, modules from the Q.series X are used for connecting the sensors (Q.bloxx-XL A108, Q.bloxx-XL A101) and the controller (Q.station-XB) for connecting and handling the modules as well as for calculations and transmission to the cloud. In the current example, the system is completed with the 3-axis ASC 5511LN accelerometer from Althen, which is connected to the Q.series X modules. In addition to the acceleration, the temperature, the humidity (representing the moisture of the building substance in the bridge) and a potentiometer (representing a displacement measurement of the expansion joint of the bridge) are monitored.

IIoT data in the result

The IIoT complete system enables convenient remote monitoring in almost real time. From the analysis of the data over a longer period of time, changes in the structure as well as material fatigue can be detected. Likewise, conclusions can be drawn about possible defects and thus also about the remaining operating time of a bridge. The Althen sensors are currently being read out at three different speeds. They deliver data via the Gantner infrastructure to the cloud, with a measuring rate of 10 Hz, 1 kHz, 10 kHz.

Effective data collection and pre-evaluation

Tests have also already been carried out with the highest possible measurement speed of 100 kHz. However, these measurement speeds are currently not absolutely necessary in reality and would unnecessarily increase the demands on bandwidth and server capacities. At the same time, however, they demonstrate the future-proof nature of the platform in terms of performance and scalability.

Limitation and pre-evaluation also make sense with the existing configuration, since even with just a few sensors, large amounts of data result from the raw data. For example, a sensor measuring vibrations at 1,000 kHz 24 hours a day would result in about 345 GB per day and about 126 TB per year. Based on the application example with 15 measured values, this would correspond to 1,892 TB of raw data per year.

Accordingly, a pre-evaluation based on algorithms is already carried out in the controller on site (EDGE computing) after appropriate configuration, but also in the cloud, in order to reduce the data volume accordingly. The transfer of cloud data to external analysis programmes is also possible, both via the classic CSV format and via a complete, integrable API interface. Even old, already existing data records can be fully integrated into the new, current data records via a CSV upload, processed and visualised in the same interface.

Possibility for data reduction

Event-based data collection offers another possibility for data reduction. Depending on the configuration of the parameters, data storage can also be triggered with pre- and post-trigger conditions. This also helps to keep the data volume low, as the data is only saved in the event that a specific event has occurred. Thus, in the event of an error, high-resolution data is immediately available. Furthermore, the controllers can also be updated remotely at any time via the cloud servers. For example, the data pre-evaluation can be flexibly adjusted or calibration values and sensor settings of the system can be updated. Of course, such IIoT constructions are not limited to one building, but are almost infinitely scalable via the cloud connection and the use of corresponding analytics applications. For example, a service provider in the field of geo-monitoring who has to monitor the load and damage of a large number of bridges synchronously over time is conceivable. With the solution from Althen und Gantner, he can monitor all sensors on all bridges remotely, send alarms when defined thresholds are exceeded (e.g. strain or excessive vibration amplitudes) and intervene accordingly remotely, e.g. by switching variable speed displays.

The service provider can thus offer its customer a high added value: predictive maintenance, quick damage limitation at manageable costs. Fast, location-independent remote access to the integrated systems significantly reduces the need for time-consuming and cost-intensive on-site inspections. And the good thing is that specific IIoT applications are not dreams of the future, they are a necessary reality on the way to what IDC calls "Data Age 2025". Because by then, according to the market researchers, 30 percent of all data will be used in real-time applications.