The company Axis-Shield is a world leader in inventing new markers for identifying cardiovascular and neurodegenerative diseases, rheumatoid arthritis, sepsis, vitamin deficiencies and diabetes. Spotting early signs of such conditions during routine medical check-ups means treatment can be started in a timely manner, which leads to improved patient management, either curing or managing the problem.

The compounds it develops are initially produced in low volumes, where automated processes are not appropriate. This moves to medium volume production once the product has been proven, approved and certified and the medical fraternity begin using it.

Some compounds later move into high volume production, but it is in the very nature of medical advancement that in other cases Axis-Shield will keep on improving the formulations and developing new products fairly quickly. Thus Axis-Shield has a need for highly efficient medium volume packaging solutions that guarantee accurate and consistent adherence to performance parameters.

The right level of torque

This led Axis-Shield to commission a bespoke packaging line that could handle multiple products in a variety of different packaging formats at a rate of around 500-2500 units per hour. The line fills bottles or other forms of container with the compounds, caps them, labels them, groups them into multi-packs, applies outer wrappers and overprints key data such as production date, use-by date, storage, handling and usage instructions, etc.

“Capping the bottles is a critical part of the process,” explains Dean Harper of the company. “Our line can work with two sizes of cap and each one must be tightened to just the right level of torque to within pretty tight tolerances.”

Robust Torque Sensor: high speed & non-contact operation

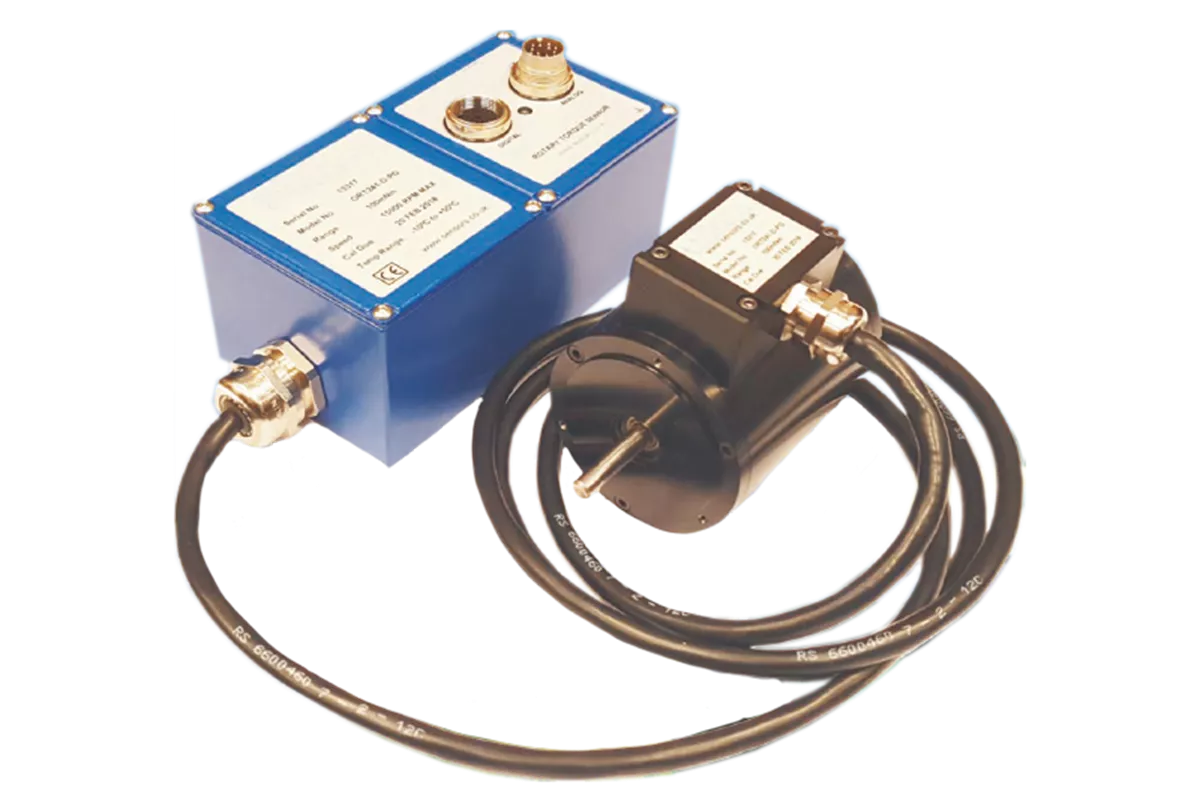

The ORT 230/240 Rotating Torque Sensor is unlike any other sensor in that it does not rely on delicate slip rings to transmit torque readings. It does this wireless using radio signals transmitted from a pick-up located near to, but not actually contacting the rotating drive shaft of the capping mechanism.“The capping process is essentially simple,” says Dean, “but you have to allow for a fast cycle time and the need to guarantee torque while ensuring total sterility.”

The Rotating Torque Sensor met the design criteria of robustness, simple high speed operation and non-contact for sterility. Mark Ingham of our partner Sensor Technology gives the details: “The ORT 230/240 Rotating Torque Sensor was ideal for this application; we just needed to work out mounting arrangements. We supplied the sensor with TorqView software which both displays readings in real time and archives them should analysis or track and trace be an application requirement.

Wireless Monitoring

Being wireless, the Rotating Torque Sensor does not need to physically contact the bottle caps or shaft of the torque head it is monitoring. Instead, sensing is achieved through a radio frequency link using Surface Acoustic Wave (SAW) sensors. A shaft twists very slightly when it rotates, the amount of deformation being proportional to the torque. The Torque Transducer measures the deformation so that it can calculate torque. To do this two tiny piezoelectric combs (SAW sensors) are glued to the surface of the shaft at right angles to one another; shaft deformation will expand one comb and compress the other. A radio frequency signal emitted by the Rotation Torque Sensors is reflected back by the combs, with its frequency changed in proportion to the combs' deformation.

For Axis-Shield, the software was required to do two things: run the torque up to a set level within tolerances, and record the actual value achieved. This secures the cap to the bottle at a level of tightness that will ensure security and sterility, yet is at a level that can be opened relatively easily by an adult. The logged values are saved to a hard drive to provide a permanent record for traceability purposes.

Dean explains: “Diagnostic fluids are distributed widely, often globally, so they may be stored for months before use. Tracing each bottle’s origin would be practically impossible without full records being automatically produced and saved to a central location.”

Used product

ORT 230/240 Rotating Torque Sensor

- Measuring range: 0,02 to 100 Nm

- Low inertia – High Speed capability

- Non contact/brushless measurement