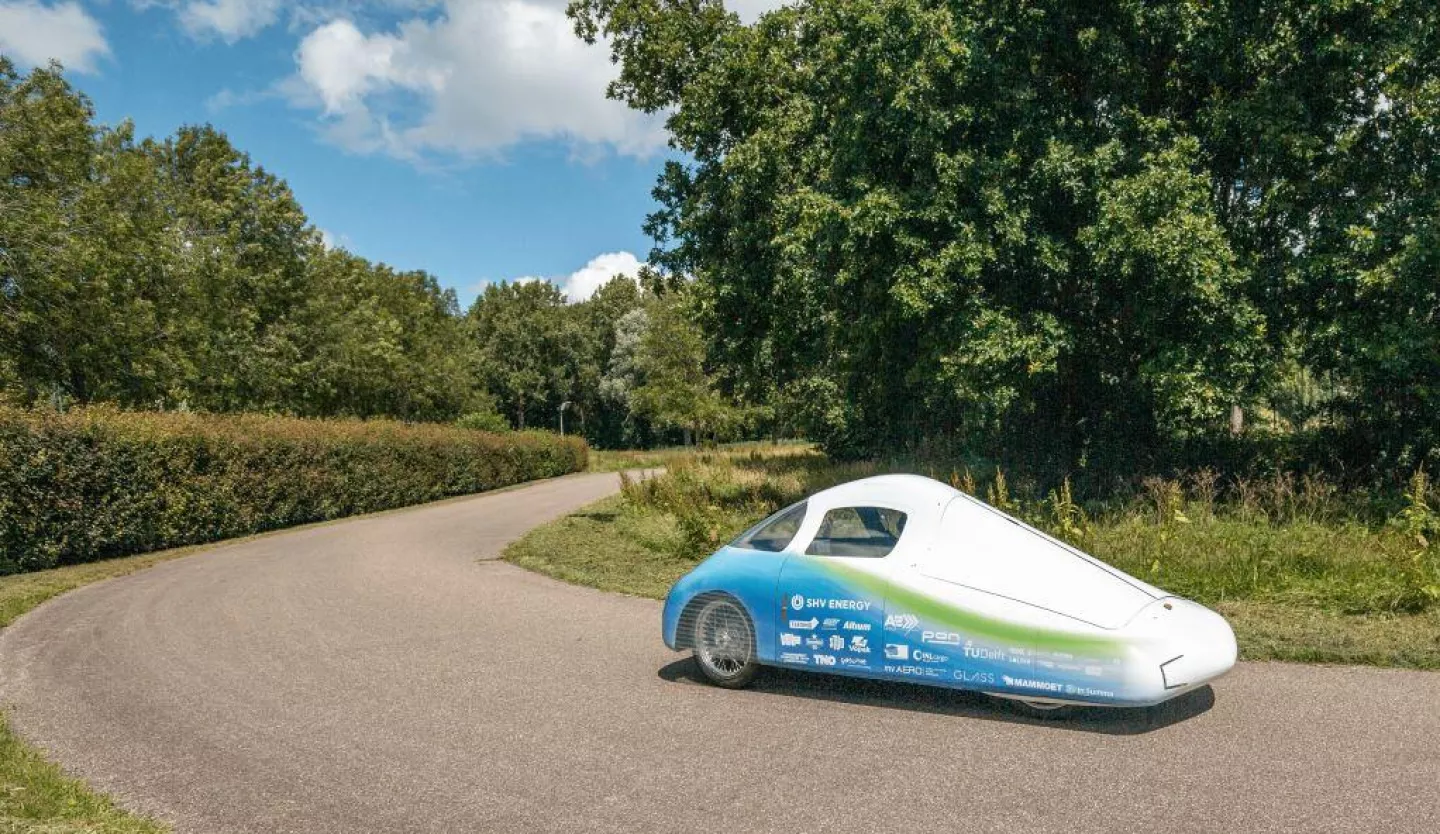

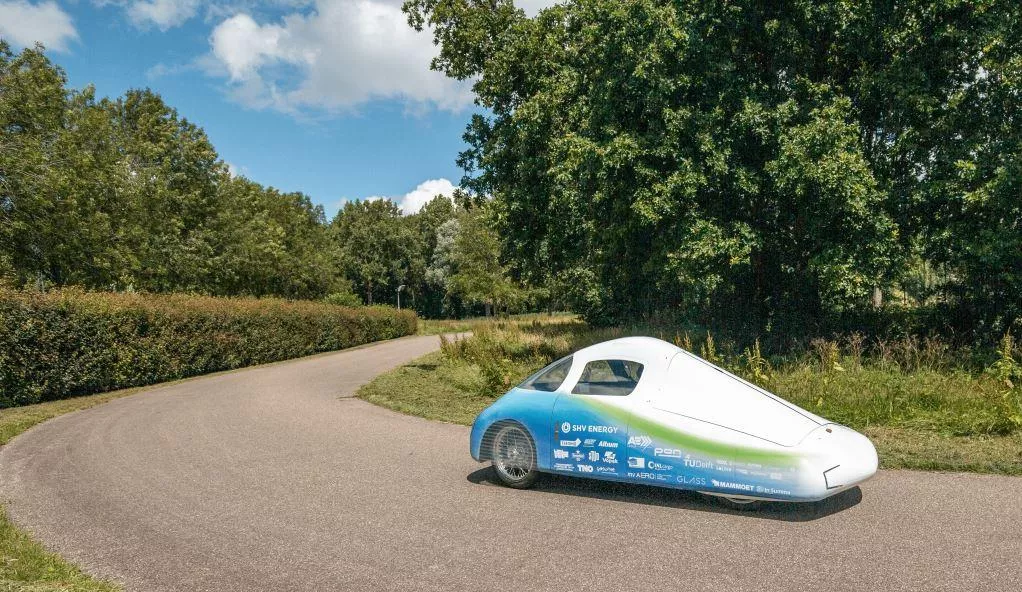

World's most efficient hydrogen-powered city car

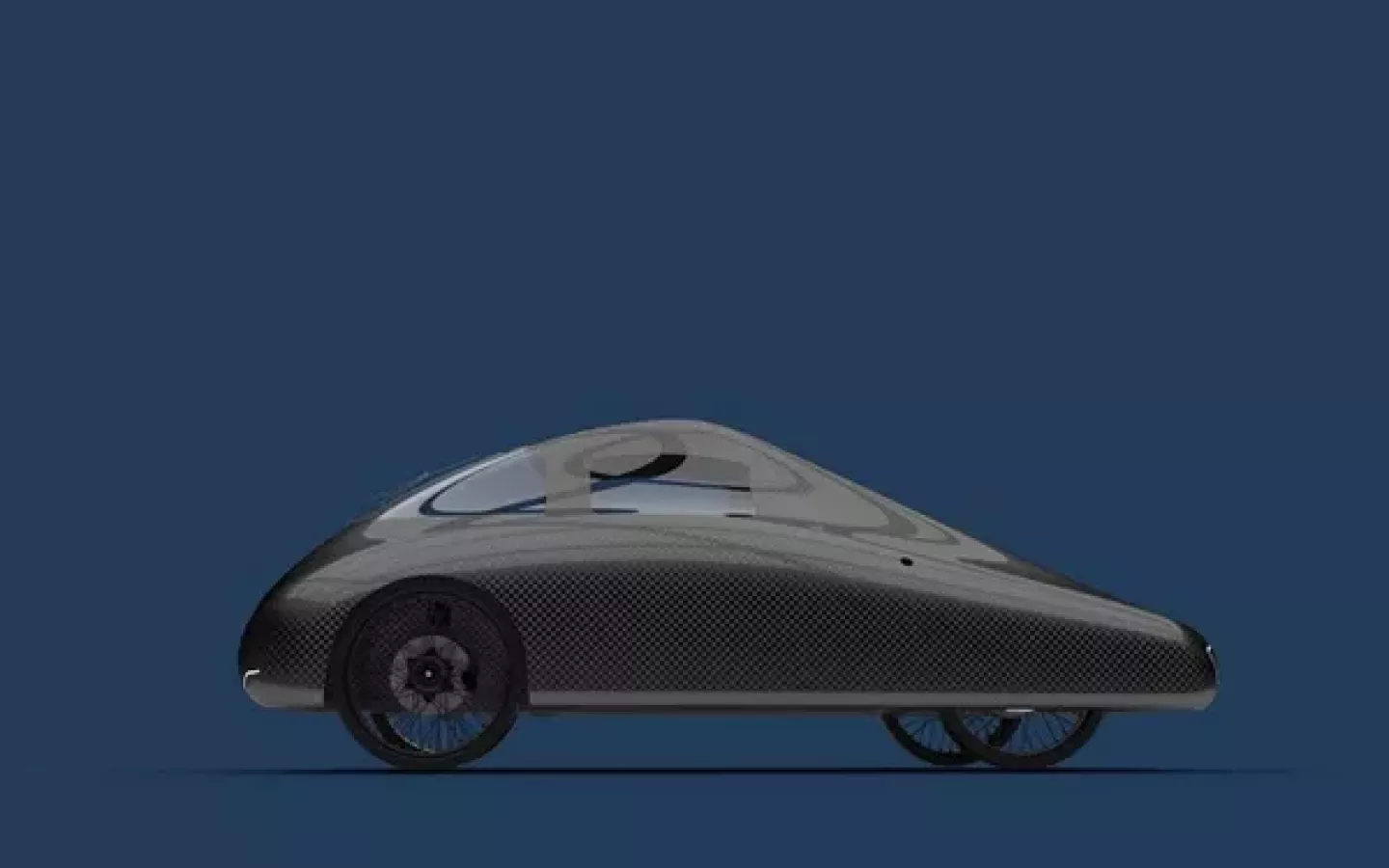

This year (2019-2020), the team chose to take on a new challenge: building not just an efficient car but building an efficient city car. This means that more practical aspects have to be taken into consideration. Examples are: making a full stop after each lap to simulate the stopping at city traffic lights, the head- and tail lights, direction indicators, and a wiper. Taking all these new challenges into account, the students started to work towards building the world’s most efficient hydrogen-powered city car.

Improving motor efficiency

In order to achieve this goal, every single element in the car needs to be as efficient as possible. Examples are the aerodynamic shape of the vehicle, the need of strong but very lightweight materials for the body and structure, and an ultra-efficient drivetrain. An electric motor is the final part of this drive train, because it is the part where electricity is converted to movement. The specifications of this motor need to be customized to our needs in order to be as efficient as possible on the track. When the production of the motor is done, tests are being performed to check if the efficiency regions are in line with the initial specifications. An important part is measuring the torque strength at various rotational speeds.

To measure the torque strength at different speeds, our sensor partner Althen helped us with the RWT430 Rotating Torque Sensor from ST Sensor Technology. This sensor is very easy to connect - both to our test bench and to a computer.

RWT430 Rotating Torque Sensor

Using the TorqView software, the team was able to get a good view of the torque strengths of the motor at different rotational speeds. In addition, they could measure the input voltage and current of the motor controller of the motor connected to the dynamometer. Also, the team was able to change the loads on this dynamometer to simulate different stages and conditions of the actual race.The information of the torque strengths and rotational speeds of the motor, gained with the TorqView software, helped to determine what the actual efficiency regions of the vehicle are. These regions matched the regions that the team calculated beforehand and showed that they had chosen a good motor setup. The strategy departments could use this important information to determine the different speeds needed for an optimal lap!.

2020 Eco-Runner achievements

Although the traditional Shell Eco-Marathon was cancelled because of COVID-19, the team did make some big achievements this year:

- Winners of the Hydrogen Endurance Race with a score of 2506,6 km/kg H2

- Winners of the Vehicle Design Award of the Shell Eco-marathon Off-Track Awards 2020. Click here to see the full video.

- Participated in the Aerodynamic Eco-competition. Click here for the aftermovie.

"We are very grateful for Althen helping us, as the Torque Sensor helped us win the “Hydrogen Endurance Race” on the 2nd and 3rd of July".

We are very grateful that Althen supported us in the development, because the torque sensor helped us to win the "Hydrogen Endurance Race".

Accept the marketing cookies to view this video.

Click here to change your consent.