About the Wireless wheel load system

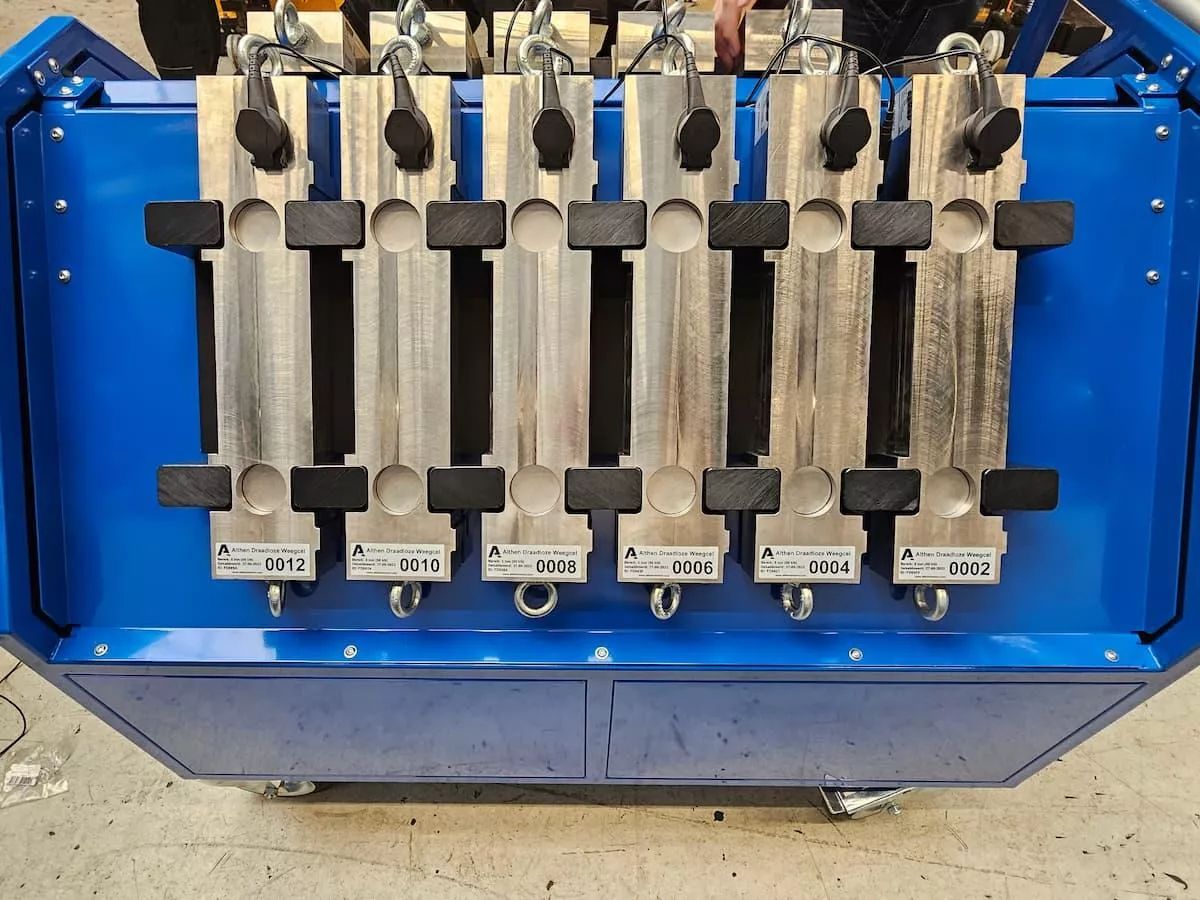

Althen Sensors & Controls delivered a robust, wireless, static weighing system to meet these needs. Known as the Wireless Wheel Load System, it provides precise measurements of the total weight of each tram, the axle loads, and the weight of each independent wheel. The system includes a mobile charging station with in GVB's case 12 load cells and a laptop equipped with custom weighing application software, creating a highly portable and easy-to-use solution that can be operated directly within the GVB workshop in Amsterdam.

The usage of this Wireless wheel load system

Knowing the weight per wheel and axle is important for any train or tram operator because of the load distribution of the tram. If the tram has an unbalance load distribution, it could lead to extra wear of the wheel or rail and potentially cause defects and damage of the wheel, rail or vehicle. The system is used in various situations to determine the weight:

- When new rolling stock is entering the network for the first time, the system can be used to check the total weight of the vehicle (to see if it is according specification) and to see of the load distribution is correct.

- When additional systems are installed in/on the vehicles the load distribution and total weight could be verified.

- Before and after heavy maintenance (e.g. overhaul of the bogie) the weight and load distribution can be checked to ensure that there is not shift in weight because of the maintenance task.

- For investigations when there is a suspicion that damage or defects are caused by incorrect load distribution on the vehicle.

GVB is weighing the vehicle at different occasions and situations to check the weight. With this system, this can be done in the workshop (depot) on the maintenance track in Amsterdam.

Weighing process simplified

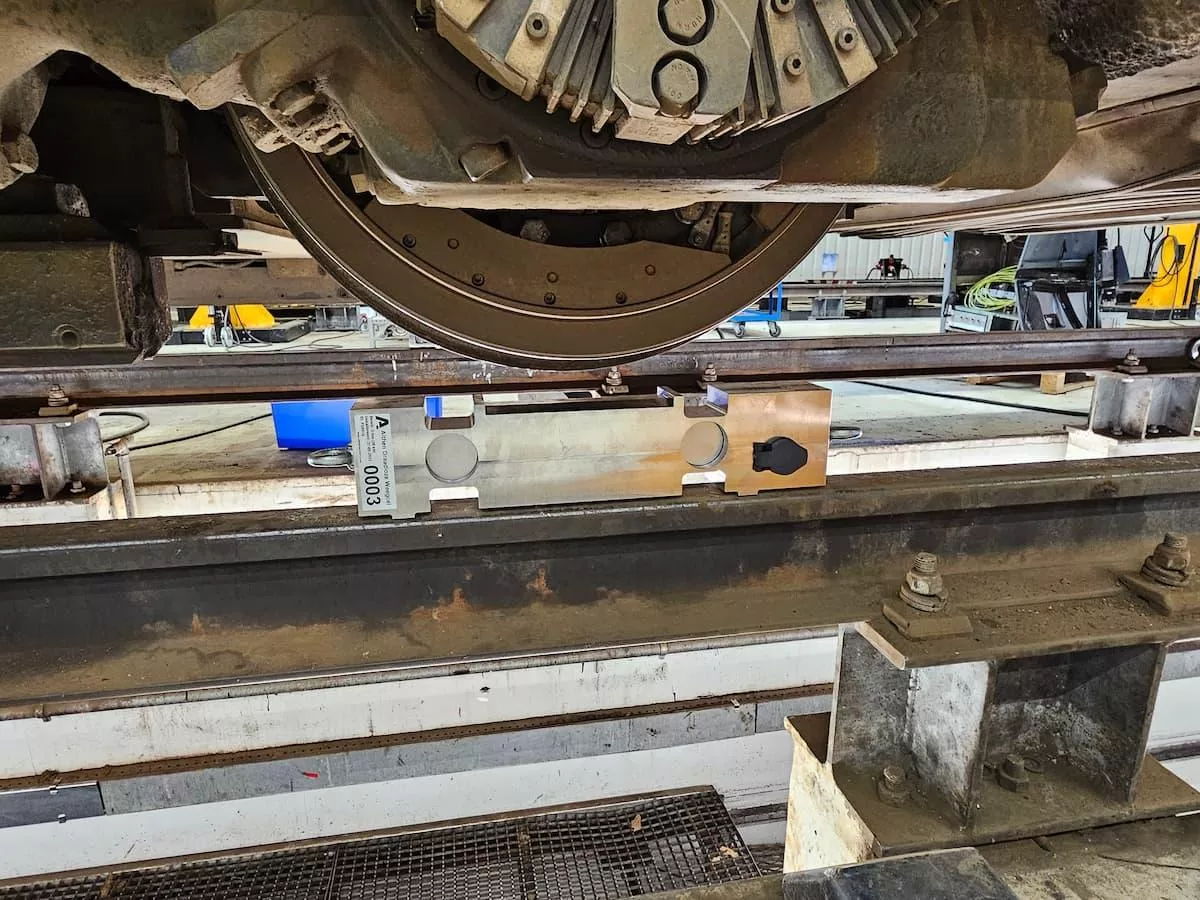

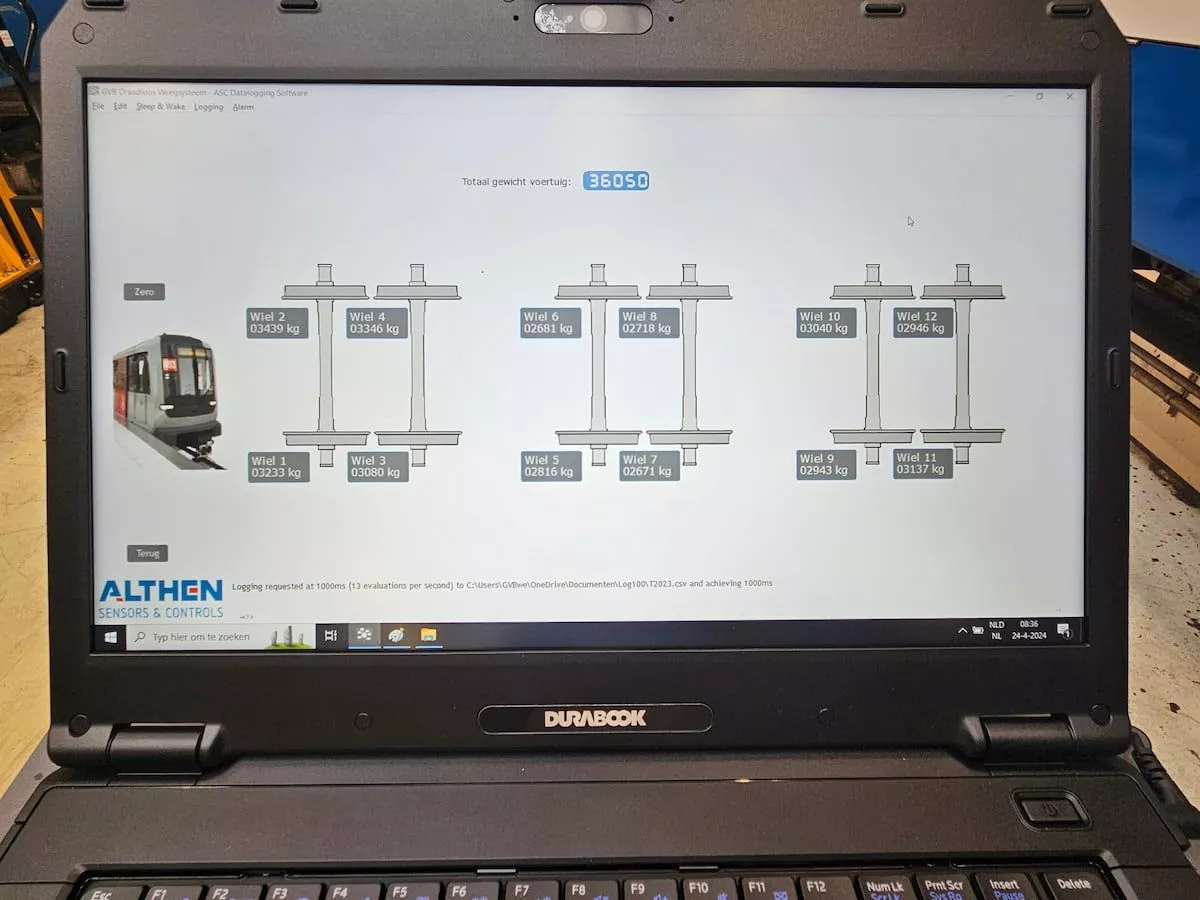

The weighing system is integrated in a mobile charging station. In the case of Amsterdam's GVB, 12 loadcells are placed on the station which charges the cells after use. The laptop contains the software to display the results per wheel, axle and total vehicle. First, the tram in question is raised on lifting jacks and the 12 load cells are placed on the rails. Before the tram is placed on the load cells, the system is “zeroed” so that a clean measurement can take place. The tram is slowly lowered so that it ultimately rests completely on the 12 load cells. Through a wireless connection, the results are sent to the laptop. Within seconds after the measuring has started, the results are displayed in the software application on the laptop.

Immediate results

For the inauguration of the system, Althen was present at the GVB workshop to show the system, how it operates and is used safely. GVB was able to prepare its own work instructions which could be verified by Althen when needed.

Regarding the tram in question that was on the load cells when the inauguration of the system was done at the GVB workshop, the results showed an unbalance between wheel 1 & 2 and 3 & 4 of more than 200 kilograms. The issue needed further investigattion by the specialists. Regarding the total vehicle weight, the results showed that the vehicles were right on specification, which is 36 tonnes.

Other railway measurement solutions

Althen Sensors & Controls also offers a comprehensive range of other railway measurement systems designed to enhance safety, performance, and operational efficiency for rail operators. We also provide systems for Weighing in Motion (AWIM), which enables precise measurements of axle loads, wheel weights, and overall vehicle weight while trains are in motion. This dynamic system is equipped with advanced features such as wheel flat detection, overload detection, and derailment risk monitoring, giving operators real-time insights into potential maintenance issues before they escalate.Customer-focused solutions in public transportation

In a short time Althen’s Wireless Wheel Load System has become an invaluable asset for GVB, allowing accurate, real-time weight measurements that support maintenance, safety, and operational efficiency. With our support, GVB now has a versatile solution for both static weighing in the depot and, potentially, dynamic monitoring in the future.

The system exemplifies our commitment to innovative, customer-focused solutions in public transportation. Let’s drive safety and precision together—reach out to us for your railway measurement solution now.