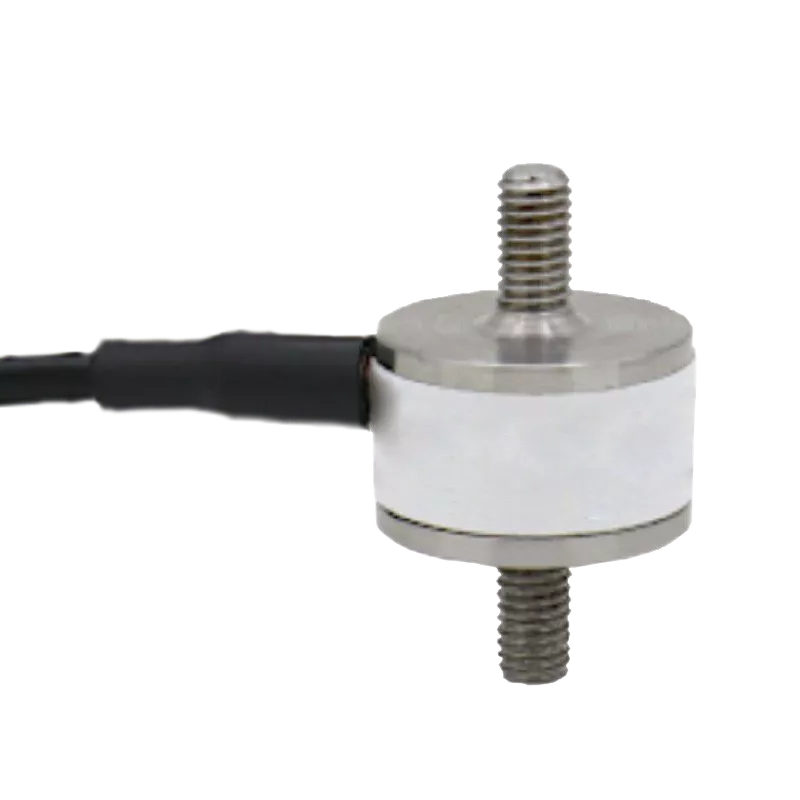

ALF251 Miniature Force Sensor

Miniature loadbutton cell for force measurement in confined spaces

Key features

- Miniature diaphragm loadcell

- Measurement range: 100N, 200N, 400N, 800N, 1.6kN, 3.2kN

- Tension, compression and bi-directional

- Non-lin./hysteresis: 0.5/0.5% RL

- Dimensions (mm): Ø20 x 13

- Easy installation

- Sealed to IP65

About the ALF251 Miniature Force Sensor

The ALF251 is ideally suited to force measurements in confined spaces in both tension and compression for control of critical parameters in all kinds of industrial processes. Their versatility is such that they are also applied in a great number of important fields of scientific and engineering test work, mobile as well as workshop, static and dynamic.

We are happy to design variants of this loadcell to meet your specific requirements. Please consult our engineering department.

The 100N range is manufactured in aluminium. All other standard ranges are manufactured in stainless steel.

When this loadcell is rationalized the resistors are housed in a capsule located in the loadcell cable 100mm from the free end.

Capsule dimensions are Ø10mm by 57mm.

Geometry: Very small loadbutton cell for force measurement in confined spaces. Used in compression and/or tension on a wide range of OEM or end-user applications.

With bi-directional versions there is a small difference between the output signal for compression and tension. All standard bi-directional loadcells are calibrated in both modes and the output for each direction is stated on the test / calibration certificate.

Other features ALF251

- Tension / compression / bi-directional calibration

- Standard 2 year warranty

- Hardened stainless steel body

Notes

1. AL = Applied load.

2. RL = Rated load.

3. Temperature coefficients apply over the compensated range.

4. The load must be applied directly through the central loading axis.

Connections

The loadcell is fitted with 2 metres of PVC insulated 4 core screened cable type 7-1-4C.

Excitation + = Red Signal + = Yellow Screen = Orange

Excitation - = Blue Signal - = Green

Reverse the signal connections to obtain a positive signal in tension mode. The screen is not connected to the loadcell body.

Do you need this sensor for your next project?

Request a no-obligation quote or send us your contact details for a free, no-obligation consultation. Our sales engineers will then contact you within a maximum of 1 to 2 working days.

Product downloads

Talk to our experts

Not exactly what you are looking for? We offer standard sensors, but can also help you with sensors adapted for you or a fully customised measurement solution. Contact us for advice or pricing.

Talk to an expertTechnical Specifications

| Specification | Value |

|---|---|

| Bridge resistance | 350, O |

| Creep - 20 minutes | ±0.1, % AL |

| Excitation voltage - maximum | 10, V |

| Excitation voltage - recommended | 10, V |

| Hysteresis | ±0.5, % RL |

| Insulation resistance - minimum at 50vdc | 500, MO |

| Load direction | Tension, compression, bi-directional |

| Measurement ranges | 100N, 200N, 400N, 800N, 1.6kN, 3.2kN |

| Non-linearity - terminal | ±0.5, % RL |

| Overload - safe | 50% RL |

| Overload - ultimate | 100, % RL |

| Rated output - nominal | 1.6, mV/V |

| Rated output - rationalised | 1.0, mV/V |

| Rationalisation tolerance | ±0.5, % RL |

| Repeatability | ±0.1, % RL |

| Sealing | IP65 |

| Temperature effect on rated output per ºc | ±0.005, % AL |

| Temperature effect on zero load output per ºc | ±0.03, % RL |

| Temperature range - compensated | -10 to +50, ºC |

| Temperature range - safe | -10 to +80, ºC |

| Weight - nominal (excluding cable) | 8 to 11, g |

| Zero load output | ±4, % RL |