Linear inductive position sensors in paper making machines

Precise and reliable measurement of position changes

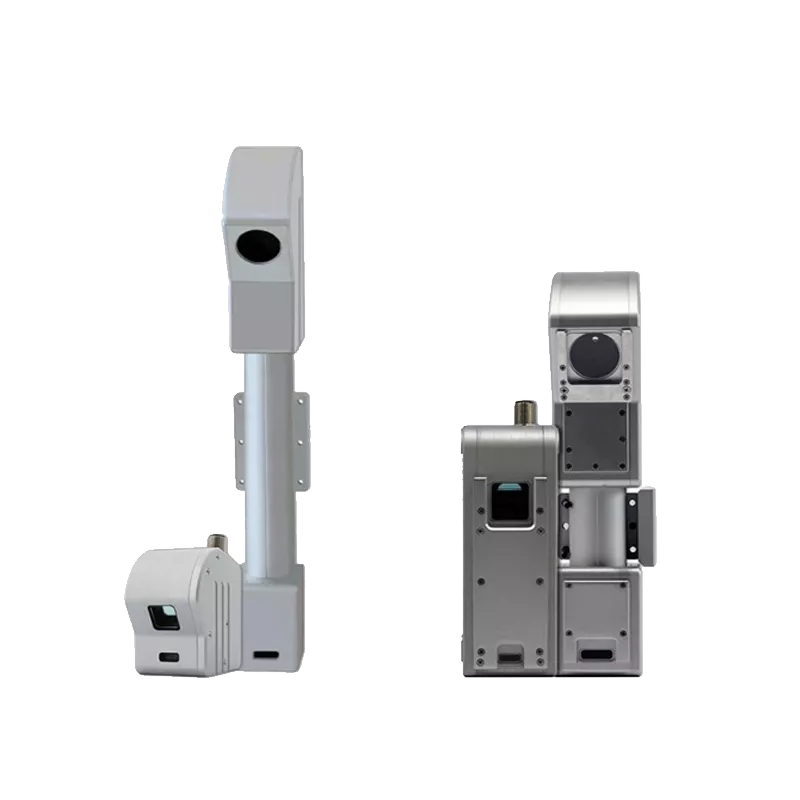

Linear position sensors measure the distance between an object and a point of reference, as well as changes in position. They do this by converting displacement into an electrical output. A wide variety of measurement principles can be used to let you make precise and reliable measurements for a broad range of applications. Linear position sensors and measurement systems are used in industrial applications as well as in scientific laboratories.

We offer standard linear position sensors but can also help you with a customized design or a complete measurement solution.

Linear position sensors are devices that measure the displacement or position of an object in a straight line. These sensors convert mechanical motion into an electrical signal, allowing for precise monitoring and control in a wide array of industrial processes. They find applications in sectors such as automotive, aerospace, manufacturing, and robotics.

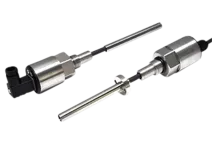

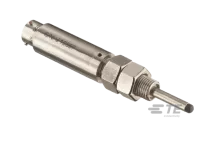

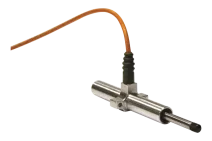

We offer linear position measurement technology for a wide range of applications requiring travel, distance, or position measurements. Our linear position sensors include conventional inductive sensors and displacement sensors, but also specialized sensors that are suitable for OEM applications. Cutting-edge contactless eddy current sensors round off our portfolio. Althen linear position sensors are based on different physical principles. This enables us to provide the ideal sensor for your application. Our linear position sensors can be divided into contacting and non-contacting position sensors. We also supply intrinsically safe EX position sensors for Ex II 1G, Ex II 1GD, and Ex i/II M1/1GD hazard zones. These position sensors are available in various configurations. Machine equipment requires heavy duty sensors. The sensors need to be reliable, durable and accurate. Our linear & rotary sensors will help you save (maintenance) costs and can be part of your automation and digitalisation program. Whether the production is small scale or mass production, manufacturing quality goods, requires quality equipment. Our sensors are designed for heavy duty applications, while also offering you long-lasting life expectancy, exceptional repeatability, high linearity, and customizable lengths for various applications.

They usually involve a direct mechanical connection between the sensor and the moving part. Potentiometric sensors are a common type of contacting linear position sensor. They use a resistive element and a wiper that makes physical contact with the surface. As the object moves, the wiper slides along the resistive element, creating a variable voltage output.

Rely on various technologies to detect the position without direct contact.

Choosing between contacting and non-contacting linear position sensors depends on the specific requirements of the application, including factors such as precision, environmental conditions, and the durability needed for long-term use. Contacting sensors are often used in applications where cost is a critical factor, and physical contact is permissible, while non-contacting sensors are preferred for high-precision applications and environments where wear and tear need to be minimized.

Machine equipment requires heavy-duty sensors. The sensors must be reliable, durable and precise. Our linear and rotary sensors help you save (maintenance) costs and can be part of your automation and digitalisation programme. Regardless of whether it is a small batch or mass production, manufacturing quality products requires quality equipment. Our sensors are designed for high performance applications and offer you long life, exceptional repeatability, high straightness and customised lengths for various applications.

As technology continues to advance, the demand for accurate and reliable linear position sensors will only grow. Althen Sensors & Controls remains at the forefront of this industry, providing innovative solutions that empower industries to achieve precision and efficiency in their operations. Whether in automotive, manufacturing, or aerospace, the use of high-quality linear position sensors is a testament to the ongoing evolution of industrial automation and control systems.