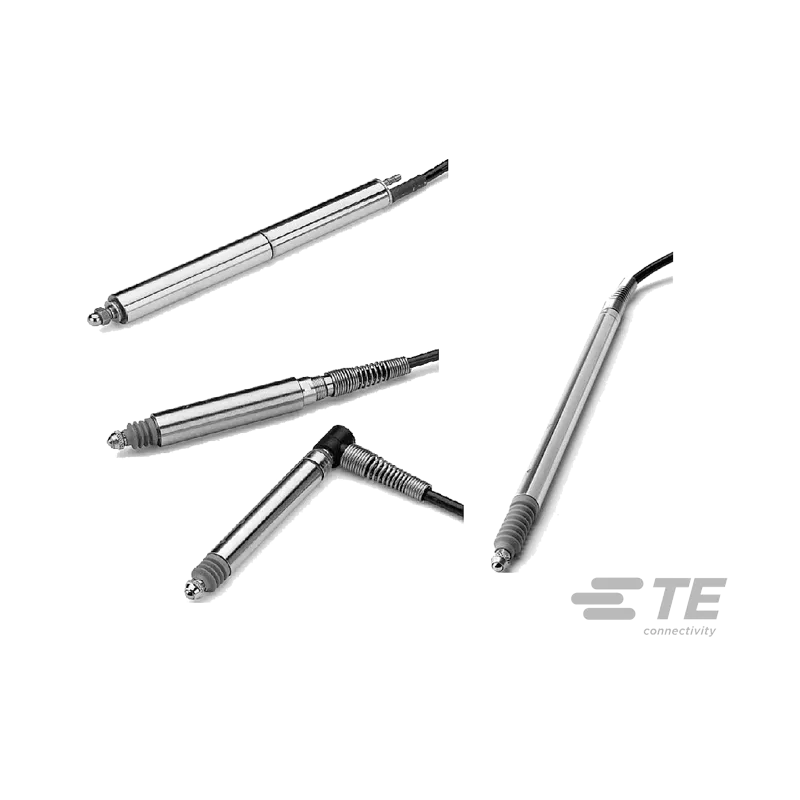

LBB Series LVDT Position Sensor

Linear ball bearing system within the gaging probe reduces radial play to a minute level and minimizes friction

Key features

- Industrial AC-operated gage head

- Removable Tungstend Carbide Contact Tip for Long-term Reliability and Interchangeability

- Double-shielded LVDT for Greater Protection from Effects of Magnetic Materials

- Polyurethan-jacketed Cable Enhances Flexibility and Improves Chemical Resistance

- Standard Viton Boot for Greater Resistance to Chemicals and High Temperatures

About the LBB series Ultra-precision Gage Heads

Linear Ball bearing design, spring-extend and air-extend

The Linear Ball Bearing (LBB) series of dimensional gaging probes is engineered for highly precise and repeatable measurements in quality control and metrology applications. LBB within the gaging probe minimize radial play and friction for ultra-precise measurement. Bearing assemblies utilize two circum ferential rows of miniature balls held in position by a retainer. The balls ride on a non-rotating plunger hardened to Rockwell 65, hard-chromed plated and precision ground for optimal repeatability and resistance to brinnelling. the contact end of the plunger has a removable tungsten carbide ball tip, with an AGD standard 4-48 U NF-2A threading.

Plunger and bearings are enclosed in a cylindrical housing, hand-honed and fit to the ball bearing assembly. Precision fitting provides for exceptional gage head repeatability. With the bearings and housing essentially matched in hardness, the plungers can better tolerate side loads for a longer unit life.

LVDT Configuration

A Linear Variable Differential Transformer (LVDT) is contained in the opposite end of the tubular housing. With no physical contact between its core and coils, the LVDT produces a highly repeatable, low noise output voltage linearly proportional to prove displacement. Output can be sensed, amplified and displayed with any Althen LVDT compatible signal conditioner, digital readout or LVDT computer based system.

LBB gage heads feature a unique two-piece construction. Units, therefore, are reparable should either probe structure or cables become damaged. A bend relief spring prevents cable damage at lead exit.

Positive mechanical stops prevent damage to the LVDT from severe impacts the end of the contact tip in cases of overstroke.

Applications for LBB Series

- Point-of-Manufacture status of production process standards

- On-line Inspection of Automobile Bodies

- Process Feedback for Numberically-Controlled

- Machine Tools

- Automated Data Collection For Factory SPC

- Robotics

Gage ranges

- ±0.020" Spring-extend

- ±0.040" Spring-extend

- ±0.100" Air or Spring-extend

- ±0.200" Spring-extend

Gaging methods

- Spring -Extend Gage Heads

Standard spring-extend LBB gage heads possess user-adjustable pretravel/overtravel settings. Units are available in both 3.15" (8 mm) and 0.375" (9.5 mm) diamters, with the latter available in both threaded and non-threaded housings A0.375" (9.5 mm) diameter, plain or threaded sleeve, can be provided for OEMS who want to stock one model with two diameters. - Air-Extend, Spring-Retract Gage Heads

Air-extend, spring-retract units are manufactured in a ± 0.100" (± 2.5 mm) gaging range. These units require dry, oilfree air at 5 to 15 psi (0.34 to 1 bar). by varying air pressure, users can control gaging force to ensure the probe does not damage finely finished surfaces or distort delicate parts. Air extend models are available in 0.375" diameters with either threaded or non-threaded housings.

Do you need this sensor for your next project?

Request a no-obligation quote or send us your contact details for a free, no-obligation consultation. Our sales engineers will then contact you within a maximum of 1 to 2 working days.

Product downloads

Talk to our experts

Not exactly what you are looking for? We offer standard sensors, but can also help you with sensors adapted for you or a fully customised measurement solution. Contact us for advice or pricing.

Talk to an expertTechnical Specifications

| Specification | Value |

|---|---|

| Housing material | High carbon, heat-treated tool steel |

| Measurement range | 12.7 to 254mm |

| Non-linearity | ±0.25% FR |

| Operating temperature | +5°C to +60°C |

| Output | 350 to 700mV/V |

| Rating | IP60 |

Related products

Need something else?

LCIT Series LVDT Position Sensor

- DC-operated model

- Measurement range: 3.17 to 114.3mm

- Non-linearity: ±0.1% FR

M-12 Series LVDT Position Sensor

- Layer-wound AC-operated model

- Small 12mm diameter case

- Low temperature coefficient of sensitivity

MHR Series LVDT Position Sensor

- Miniature AC-operated model

- Compact size

- Lightweight / low mass core