Products

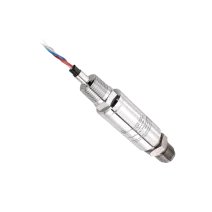

General purpose pressure sensors

- Measuring range -1 to 10.000 bar

- Standard Low-cost

- Variety of options available

Miniature pressure sensors

- Measuring range 0 to 1.000 bar

- Excellent performance in harsh conditions

- Compact size, highly reliable

Pressure sensor modules

- Integrated signal conditioning.

- Pre-calibration and compensation.

- Ease of integration and communication.

(Ultra high) precision pressure sensors

- Measuring range 0 to 5.000 bar

- Accuracy from 0.75% to ≤ 0.01%

- Wide range operating temperatures

Pore pressure sensors

- Precision measurement with vibrating wire technology

- Rugged design for extreme environments

- Comprehensive data solutions with wireless connectivity

Differential pressure sensors

- Measuring range 0 to 500 bar

- Based on the piezoresistive technology

- Accuracy from 1.0% to 0.1%

Our offer to you

We offer standard pressure sensors but can also help you with a customised design or a complete measurement solution.

Low pressure sensors

- Measuring range 0 to 1 bar

- High accuracy at low pressure

- Low hysteresis & long-term stability

Hygienic and process pressure sensors

- Sanitary design for hygienic sensors

- Robust construction for process sensors

- High accuracy and compliance with industry standards to ensure safety, efficiency, and regulatory compliance

Intrinsically safe pressure sensors

- Measuring range 0 to 1.600 bar

- ATEX approved for hazardous areas

- Durable, stable, reliable & accurate

Submersible pressure level sensors

- Measuring range 0 to 1.000 bar

- Submersible, waterproof protection rating

- Accuracy from 0.5% to 0.1%

Subsea pressure sensors

- Extreme durability and corrosion resistance

- Unmatched accuracy and stability

- Comprehensive depth and pressure range

Hydrogen pressure sensors

- High sensitivity and accuracy

- Durability and corrosion resistance

- Safety compliance

Wireless pressure sensors

- Measuring range 0 to 1.000 bar

- Digital outputs [24 - bitADCI2C]

- Heavy Industrial CE Approval

How pressure sensors work

Pressure sensors are devices that detect and measure the pressure of a gas or liquid. They convert the physical pressure into an electrical signal, enabling accurate pressure monitoring and control in various applications. Pressure sensors utilize different technologies such as strain gauges, capacitive sensors, piezoelectric, or resonant frequency principles. They play a vital role in ensuring safety, optimizing processes, and enabling precise measurements. Pressure sensors work based on the principle of detecting and converting physical pressure into an electrical signal. These sensors utilize different technologies to achieve this.

One common technology is the strain gauge principle. Strain gauge pressure sensors consist of a thin conductive film bonded to a flexible diaphragm. When pressure is applied, the diaphragm deflects, causing strain in the conductive film. This strain alters the electrical resistance of the strain gauge, which is then measured and converted into an electrical signal representing the applied pressure. Althen Sensors offers both digital and analog output options, allowing you to choose the best format for your application and data processing needs.

Professional pressure measurements made easy

We offer a wide selection of pressure sensors for use with liquids and gases in all industrial applications. You can also benefit from our extensive services surrounding sensor and measurement technology: From pressure sensors and transmitters to barometers and differential pressure sensors, standard or miniature configurations, with and without ATEX certification.

What advantages do our pressure

sensors provide?

- high-precision measurement of absolute, relative and differential pressures

- suitable for static and dynamic measurements

- long service life, can also be used under extreme conditions

- many different designs for a wide range of applications (e.g. for air/gases, various liquids and for use under water)

- suitable for all installation conditions (e.g. miniature designs or wireless pressure transducers)

- enable static measurement and control of very low differential pressures (from 5 to 1000 mbar)

- fulfil the "proof of intrinsic safety" according to Directive 94/9/EC ATEX if required

-

CustomizationPressure sensors can be customized to fit specific requirements, ensuring that clients get the perfect solution for their unique needs.

-

Rugged and reliableMany industrial applications involve harsh environments, where sensors are exposed to extreme conditions. Pressure sensors are designed to be rugged and reliable, capable of withstanding challenging surroundings.

-

Comprehensive technical supportOur team of experts provides comprehensive technical support to assist with product selection, installation, and troubleshooting.

Possible areas of application for pressure sensors

- Research and manufacturing

- Building and construction

- Mechanical engineering

- Process engineering

- Aerospace technology

- Automotive industry

- Laboratory applications and medical technology

- Food industry

- Industrial control and regulation technology

- Oil, gas and coal industry

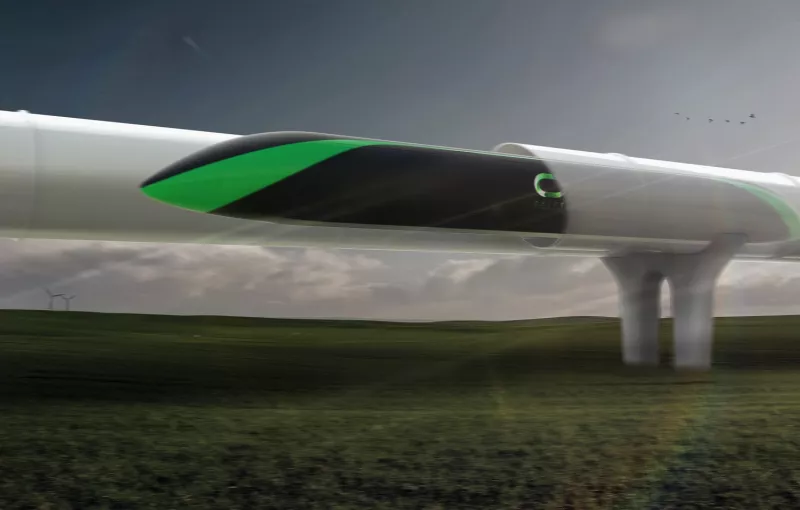

Applications and industries

In the automotive industry our pressure sensors for instance contribute to automotive systems, such as engine management, tire pressure monitoring, and fuel injection systems, ensuring safety and efficiency. Where in aerospace and defense the pressure transmitters play a critical role for altitude monitoring, flight control systems, and hydraulic systems. There are many other applications and industries for pressure sensors like for instance industrial information, offshore and the maritime sector.

Pressure sensors in action

Discover our pressure sensor projectsOur services

Custom solutions for pressure measurement

Althen also offers a broad selection of custom solutions for pressure measurements in your specific applications. By offering customization options, we ensure that their pressure sensors can be tailored to the unique needs of each client and application. This level of flexibility allows our clients to achieve optimal performance and efficiency in their systems while maintaining the highest levels of accuracy and reliability. It also demonstrates our commitment to providing solutions that address the specific challenges and demands of our customers. In order to identify the right sensor for your application, we start by checking all the requirements. This includes the following information:

- Type and area of application

- Precision requirements

- Output signal

- Electrical power supply

- Mechanical pressure connections

- Environmental conditions

- Medium and temperature

- Sensor configuration and protection class