New torque sensors for pharmaceutical OEM

Explore the precision and innovation behind Althen Sensors & Controls' torque sensors, integral devices that measure rotational force for applications across industries. From automotive and industrial automation to aerospace and medical devices, torque sensors are crucial for ensuring accuracy and efficiency in diverse processes. Althen's product portfolio, featuring rotary and static torque sensors, stands out for its high accuracy, robust construction, and customizable options, making these sensors indispensable assets for modern engineering needs. Discover the principles of torque sensors, their wide-ranging applications, and how Althen's commitment to quality and innovation places them at the forefront of providing cutting-edge torque sensing solutions.

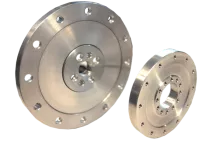

Dynamic & static torque monitoring

We offer standard torque sensors but can also help you with a customized design or a complete measurement solution.

Torque sensors, also known as torque transducers or torque meters, are devices designed to measure the rotational force (torque) applied to an object. Torque is a critical parameter in numerous applications, ranging from industrial machinery and automotive systems to aerospace and medical equipment. These sensors convert mechanical torque into an electrical signal, providing valuable data for monitoring, control, and analysis.

Conventional torque sensors use strain gauges. These convert the mechanical torque into an electrical signal. Slip rings are typically used to transfer that signal from the measurement shaft. This tried and tested technology is rugged and reliable. Rugged, high-quality slip rings enable torque measurements over extended periods. They can endure rotating at up to 5,000 or 6,000 revolutions per minute. You need to amplify or visualize the measured signal? Our torque sensors are compatible with all amplifiers and display systems from our portfolio.

Our cutting-edge alternative to strain gauge technology uses Surface Acoustic Wave devices. This technology is based on an acoustic element that changes its resonant frequency under torsion. Your advantage: Thanks to the quick signal transfer from the rotary torque sensor, you can use these transducers for rotational measurements at up to 30,000 revolutions per minute.

Althen not only provides torque transducers for rotating applications – we also offer sensors for static reaction torque. They are also available as miniature versions. These sensors for measuring torque are all based on strain gauge technology. Multi-component transducers are a special type of torque measurement sensors. They measure torque along two or three measurement axes. This allows you to measure torque and static forces along multiple axes.

Are you looking for a digital interface for torque measurements? We are happy to design a custom sensor for you that includes a digital interface in addition to the analogue output signal. The digital interface makes reading out the measuring values simple. And it lets you scale each torque sensor to a specific measurement range as required.

For perfect signal processing in torque measurement, we provide a broad range of strain gauge amplifiers. Your systems already provide amplified output signals? You can connect them to our display systems, data loggers, or PC-based measurement data logging systems.

Torque sensors represent a cornerstone in modern engineering and industrial processes, enabling precise measurement and control of rotational forces. Althen Sensors & Controls, with its commitment to innovation and quality, stands at the forefront of providing cutting-edge torque sensing solutions. As industries continue to evolve, the role of torque sensors in ensuring efficiency, accuracy, and safety will only become more pronounced, making Althen's products a valuable asset for a diverse range of applications.