Monitoring of chillers and cooling units

Reliable measurement of variable accelerations

Vibration sensors are piezoelectric accelerometers that sense vibration. They are used for measuring fluctuating accelerations or speeds or for normal vibration measurement. Maintenance professionals use the sensors in order to predict the maintenance of the machinery, to reduce overall costs and increase the performance of the machinery.

We offer standard vibration sensors but can also help you with a customized design or a complete measurement solution.

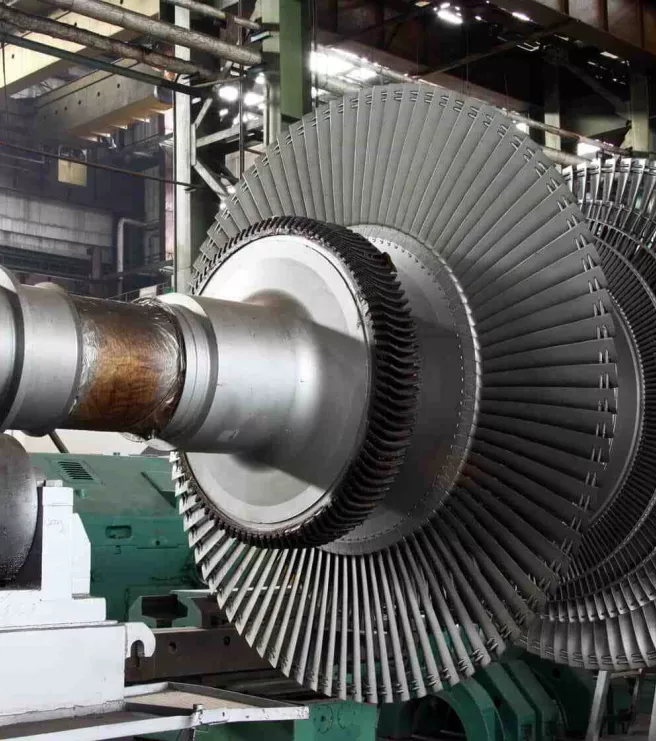

Motors and mechanical components cause vibrations in machines and plants. These vibrations should be kept as low as possible to cut back on wear and tear and avoid shutdowns. Over time, vibrations can increase due to wear and resonance. That is why many operators need to monitor the vibrations of their machines.

Vibration is measured using piezoelectric vibration sensors and matching evaluation electronics for vibration analysis. Vibration sensors are chosen based on the following criteria: required frequency range, sensitivity, and weight.

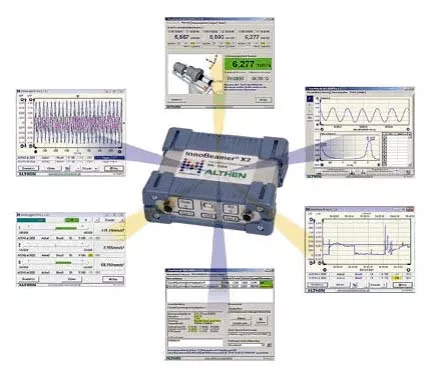

Althen provides general purpose, flexible electronic devices for vibration analysis, such as digital displays, data loggers, and long-term recorders. We also offer special software tools that we customize to suit your specific application.

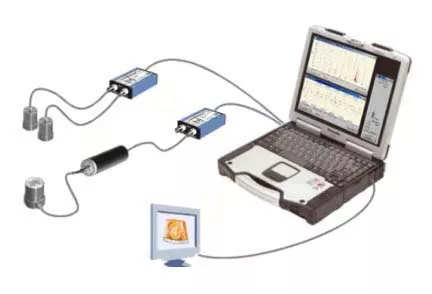

Our VibroMatrix vibration measurement system is a simple solution for measuring and analyzing vibration in industrial settings. This measurement system comprises a 2-channel A/D converter for IEPE vibration sensors and various software tools for PCs and Notebooks.

The stationary VibroLine (VLE Series 1-8) vibration measurement system lets you continually monitor machine and plant vibrations in the long term. Thanks to the device’s 4-zone display, you can check the machines’ status at any time. VibroLine conforms with the DIN ISO 10816 / 20816 standards.

Even if measuring vibrations is not a daily task for you, VibroLine lets you easily measure and assess vibrations – without requiring deeper knowledge of vibration measurement technology.

In addition to vibration sensors and software, Althen also provides vibration measurement related services. We can also configure your measurement system before delivery. What is more, we can handle the entire vibration measurement process for you – or train your employees on vibration measurement and the VibroMatrix and VibroLine systems.

Modern vibration sensors are based on a piezo-ceramic element that is put under tension by the so-called seismic mass. Under vibration, the seismic mass strikes the piezo-ceramic element like the hammer in a piezoelectric lighter. This makes the mass emit a charge, which is amplified to create a voltage signal. All our vibration sensors have an integrated signal amplifier, with the exception of some high-temperature models. This makes our vibration sensors especially easy to use.

At a glance, our vibration sensors differ almost only in size. Their form factor is primarily determined by two criteria: sensitivity and the required frequency band. To put it simply, low-frequency sensors are more sensitive and have larger casings than miniature sensors for high-frequency applications.

Industrial vibration sensors are suitable for measuring vibrations at medium strengths. These sensors have a sensitivity of 100 mV/g and their typical frequency band ranges from 1 Hz to 8000 Hz. At the lower end of the scale, the so-called seismic vibration sensors are built to detect very weak vibrations. Our reference sensor 731A has a sensitivity of 10 V/g at a typical frequency band ranging from 0.05 Hz to 500 Hz. At the other end of the spectrum, we offer vibration sensors for shock applications with measurement ranges up to 70,000 g – at frequencies well beyond 15,000 Hz.

All our vibration sensors come in stainless steel casings and are suitable for demanding industrial applications. Their standard connectors have IP67 grade protection. We also offer submersible vibration sensors for use in depths of several hundred meters.

We offer standard vibration sensors but can also help you with a customized design or a complete measurement solution.

Our specialized vibration measurement system VibroMatrix was developed specifically for use with submersible sensors. The InnoBeamer 2-channel A/D converter connects the available vibration sensors to a PC or notebook using a USB interface. The InnoBeamer’s power is supplied via USB as well, so that no further power supply is needed. It also provides the voltage required for the IEPE vibration sensors.

The vibration sensor receives its voltage using IEPE technology. The sensor requires DC voltage between 15 and 18 V at constant current. This is controlled by a constant-current diode. The output of the vibration sensor is then modulated up to BIAS voltage.

Unlike our force and pressure sensors, vibration sensors with integrated signal amplifiers require constant current power supply. That means that the supply electronics include a constant-current diode which supplies the right voltage at a constant current between 2 and 5 mA.

Our VIB-KS measurement amplifiers for vibration sensors are ideally equipped for this task. In addition to the peak-to-peak acceleration, they also output the effective value or limit contacts.