Weighing 1.680.000 kg. wind turbines with load pins

Technology at the highest level

Discover unparalleled precision in weight measurement with Althen Sensors & Controls' advanced weighing sensors and load cells. Our diverse range includes innovative technologies such as strain gauge, piezoelectric, and hydraulic load cells, each tailored to specific application needs. From the robustness of bending beam sensors to the simplicity of single-point load cells, our products excel in accuracy and durability. Featuring environmental resistance, high overload protection, and cutting-edge digital signal processing, Althen's solutions ensure reliability in challenging conditions. Elevate your precision, streamline processes, and embrace the future of weight measurement technology by exploring our customizable solutions today.

We offer standard weighing sensors and load cells but can also help you with a customized design or a complete measurement solution.

We offer a broad selection of load cells, weighing electronics, and accessories in accordance with the standards of the OIML (International Organization of Legal Metrology). Combine our hardware and software solutions including bus technology to successfully and effectively automate your industrial weighing processes.

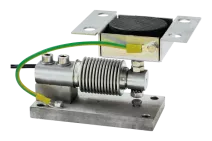

Our load cells and weight sensors can be used to build weighing stations and other systems for weighing goods. They transform a load or weight into an electronic signal. This output signal can take the form of a change in current, frequency, or voltage, depending on the type of load cell and its configuration. Every sensor is made from a durable material such as steel and fitted with one or more strain gauges. When force is applied to the strain gauge, it transmits a low electrical current. Weighing sensors can be pressure or tension based, or even bidirectional.

Our load cells consist of a measurement unit with one or more strain gauges can be deployed in parallel configuration for summation. You can use our standard strain gauge amplifiers to amplify the signal or evaluate weighing cell signals. Alternatively, we are happy to provide custom measurement systems and fully integrated solutions.

Load cells form a special section of our weighing sensor portfolio are used in weighing systems, such as scales or other devices for weighing goods. Unlike force sensors, the measurements are given in grams, kilograms, or tons. Typical load cells are based on bending or shear beams. However, you can also use low-profile force sensors or cylindrical load cells to construct weighing systems.

Our wide range of load cells for measurement ranges from 50 grams to 25 tons, as well as load pins for up to 1,500 tons. Use our simple, cost-effective load cells for OEM applications. For highly demanding applications, our high-quality submersible stainless steel load cells might be the right choice.

Accept the marketing cookies to view this video.

Click here to change your consent.

You are designing a new product or machine, and somewhere a force or weight must be measured. The standard product range of force sensors and load cells don't offer a suitable solution. What now?

Then you probably are looking for a customized load cell that exactly fits your machine or application. By strategically looking at mechanical components in your application, we can change passive components into active sensors. Our custom load cells for OEM or Test & Measurement applications in which force, reaction torque, or weight must be measured based on strain gauge technology.

Especially in case of dynamic loads, you should make sure the measurement range of your load cell isn’t too small. That way you avoid overloading them at peak loads. For instance when applying weight dynamically. Generally speaking, our load cells are very precise, so that you can use double or triple measurement ranges. When using external strain gauge amplifiers, scale your measurement signal in such a way that only the desired range is given as an output. This lets you compensate for large offset values such as the static weight of a silo or platform.

Althen Sensors & Controls invites you to explore the future of weight measurement technology. Elevate your precision, streamline processes, and unlock new possibilities with our innovative weighing sensors and load cells. Contact us today to discuss how we can customize our solutions to meet your unique requirements.