Key requirements for strain gauge coatings

A high-quality coating should meet the following essential criteria:

- Water and moisture resistance: Provides superior protection against environmental moisture and water, ensuring long-lasting reliability.

- Electrical insulation: Prevents interference that could distort measurement results, maintaining the integrity of the data.

- Strong adhesion: Guarantees a secure bond to the strain gauge, connecting wires, and test specimen, ensuring stability throughout testing.

- Structural integrity: Ensures the coating does not deform or damage the test specimen, preserving its structural properties during testing.

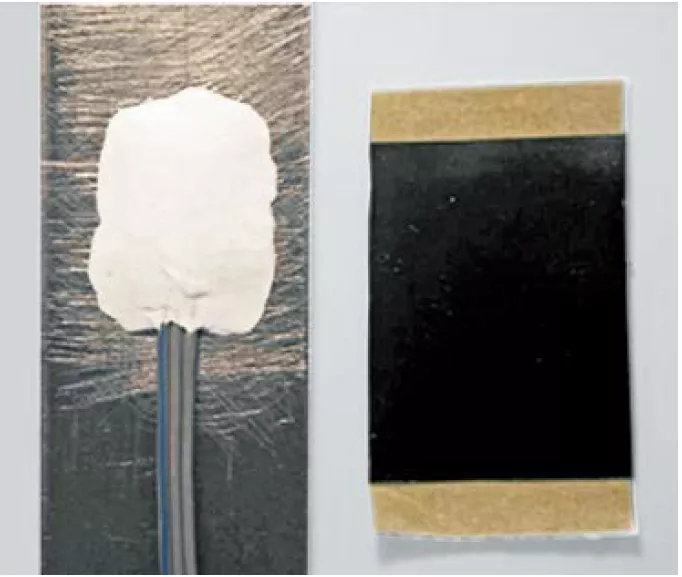

SB and VM tapes are crafted from durable butyl rubber, known for their pressure-sensitive adhesive properties. These tapes can be easily applied to the test surface with a gentle press, creating a reliable, long-lasting seal.

Step-by-step guide: applying strip coating with tape

Cutting the tape to size - first layer with SB tape

- Cut a piece of SB tape large enough to cover the entire coating area.

- In addition, cut a smaller piece of tape (5-10 mm long) that fits under the connecting wires.

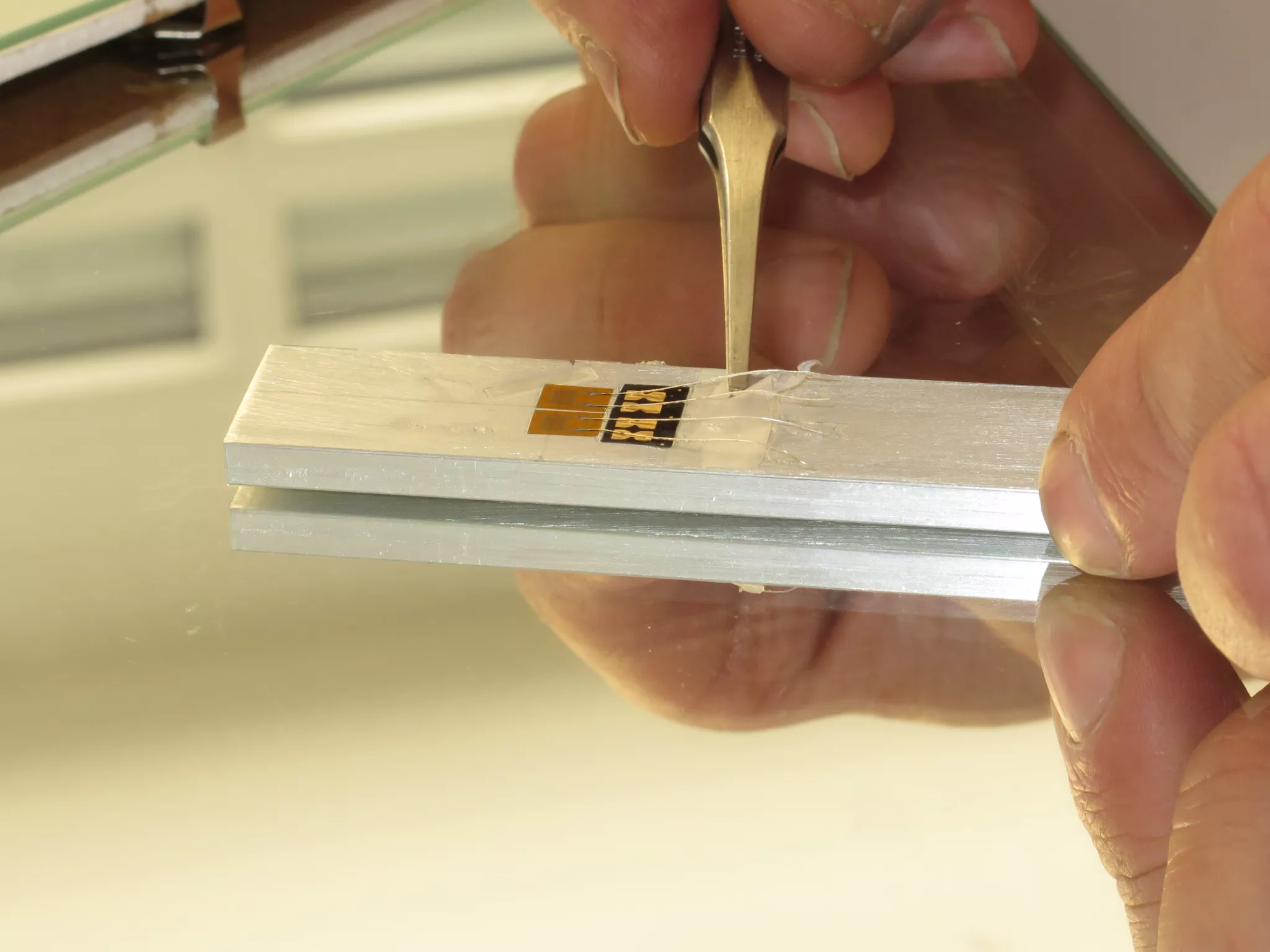

Underlaying the tape

- Carefully lift the connection wires.

- Press the smaller piece of SB tape firmly onto the surface of the test sample (DUT) under the connection wires. This provides a base layer for protection.

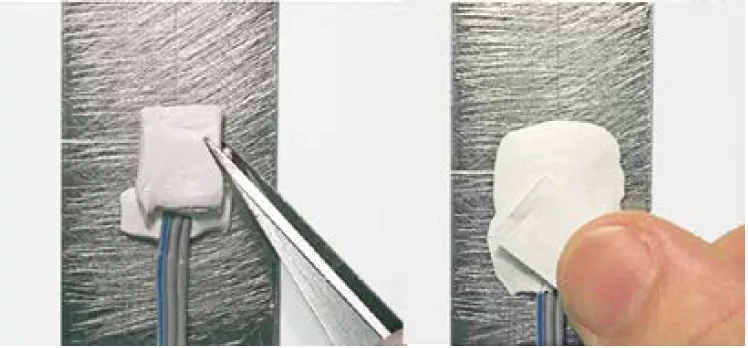

Complete coating with SB tape

- Place the connection wires back onto the small piece of tape.

- Carefully apply the larger piece of SB tape over the strain gauge and the connecting wires. Ensure the surface is smooth and fully covered to provide maximum protection.

Finishing the coating with VM tape

- Cut a piece of VM tape that is slightly larger than the SB tape coating layer.

- Carefully press the VM tape onto the area, ensuring it completely covers the SB tape layer for full coverage.

Advantages of SB and VM strain-gauge coating tapes

- Superior protection: These tapes offer excellent resistance to moisture, water, and environmental factors, ensuring long-lasting protection.

- Durable and reliable: Designed to preserve the integrity of the strain gauge, they prevent deformation of the test specimen, maintaining accurate readings.

- Easy to apply: With their pressure-sensitive adhesive, these tapes are simple and quick to apply, making installation hassle-free.

Tailored for Precision: Engineered to meet the rigorous demands of strain gauge applications, these tapes provide dependable protection under a variety of challenging conditions.

Related products

VM Tape butyl rubber

- Excellent moisture and water resistant characteristics

- Easy-to-use

More information

Do you have questions about strain gauges?

Need more information about strain gauges or perhaps additional questions or a quotation? Contact our technical experts, who will be happy to help you further.