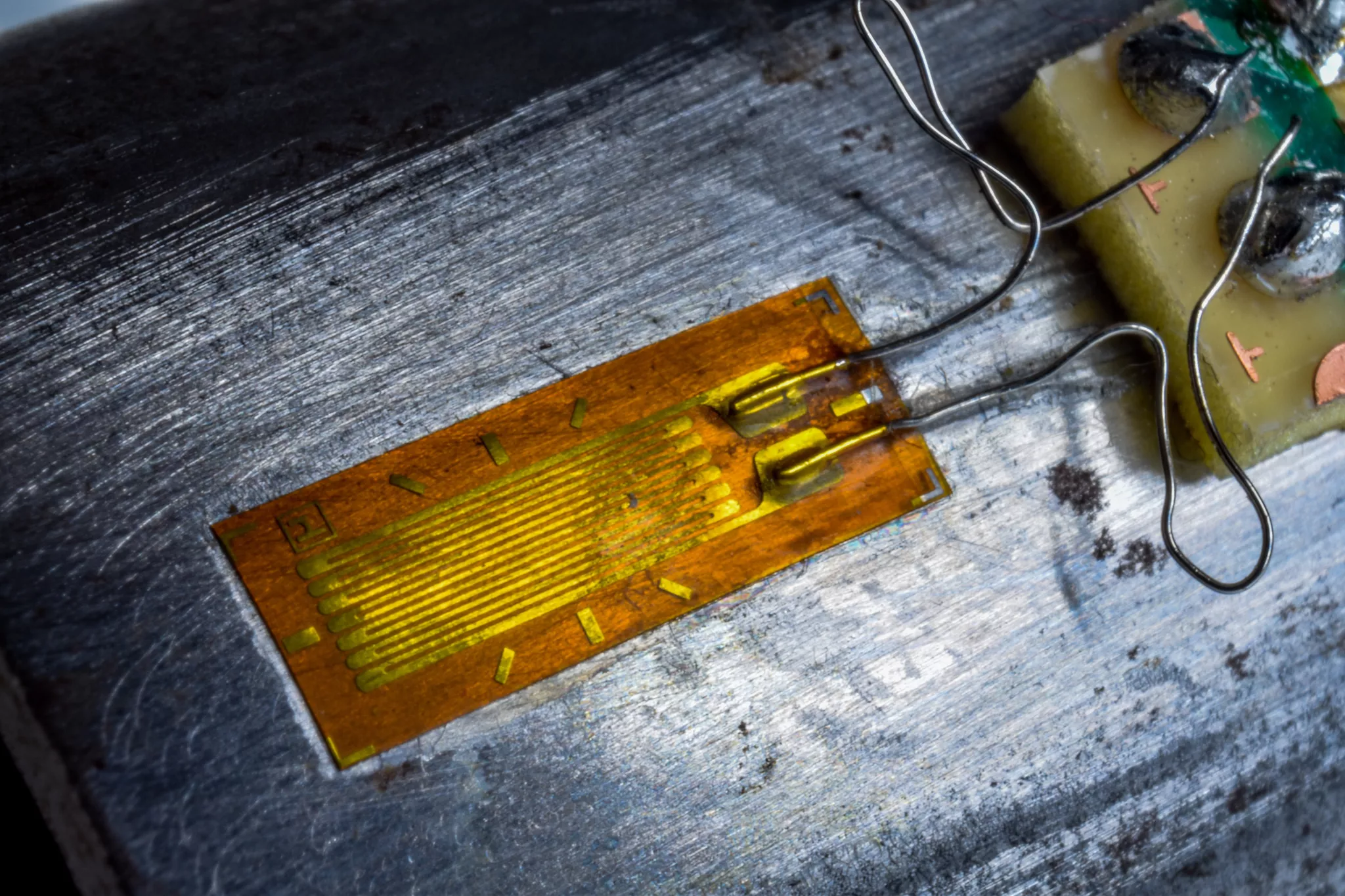

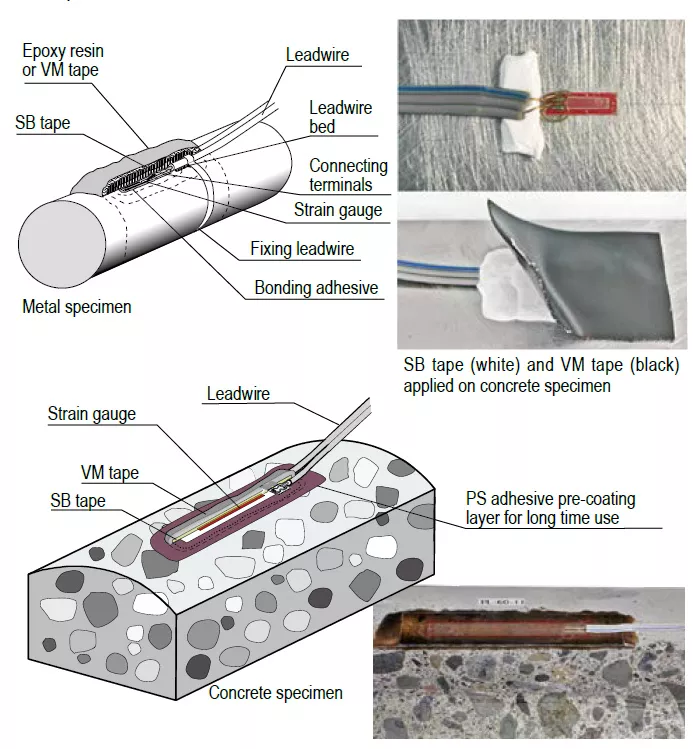

Gluing of strain gauges

The most common method for installing strain gauges is bonding, which is widely applicable to various materials, including:

- Metal

- Concrete

- Wood

- Composites

Features and benefits of bonding:

- Versatility: This technique is suitable for a wide range of materials that can be effectively bonded.

- Accurate measurements: Bonding ensures a stable and reliable attachment of the strain gauge, contributing to precise and consistent measurements.

- Protection post-installation: After installation, protective coatings are applied to safeguard the strain gauges and wiring from environmental factors like moisture, dust, and other contaminants.

Temperature resistance:

The choice of adhesive is crucial and depends on the maximum operating temperature. Many adhesives can withstand temperatures up to 300°C, ensuring durability under various conditions.

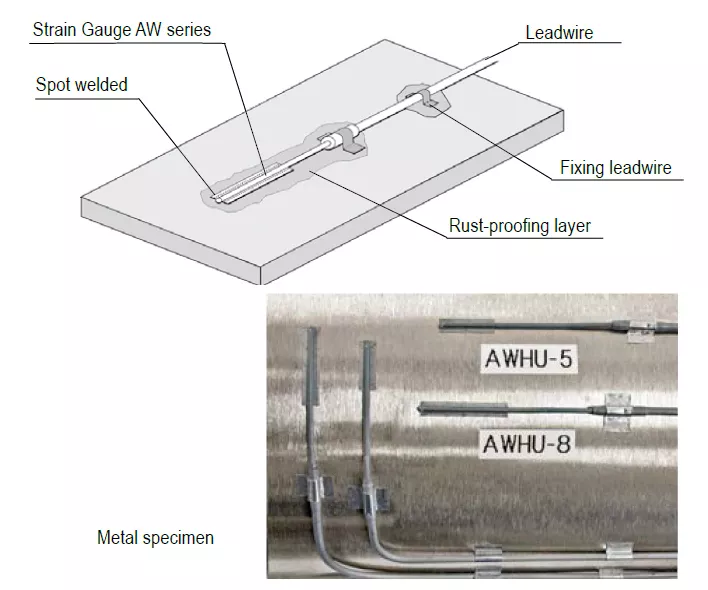

Spot welding of strain gauges

For applications exposed to high temperatures and harsh environments, such as gas-filled or underwater conditions, spot welding offers an ideal solution.

Features of spot-welded strain gauges:

- High temperature resistance: Designed to withstand operating temperatures ranging from -196°C to +800°C, making it suitable for extreme thermal conditions.

- Durable design: The strain gauge is fully encapsulated in a metal tube, providing robust protection against harsh environments.

- Strong attachment: Spot welding creates a secure and reliable bond, ensuring the strain gauge remains intact under high temperatures and heavy loads.

Ease of installation:

The W-50RC spot welding device, specifically engineered for this technique, simplifies the installation process, making it accessible even to users without technical expertise.Important: Ensure that the test material is a metal compatible with spot welding to guarantee optimal results.

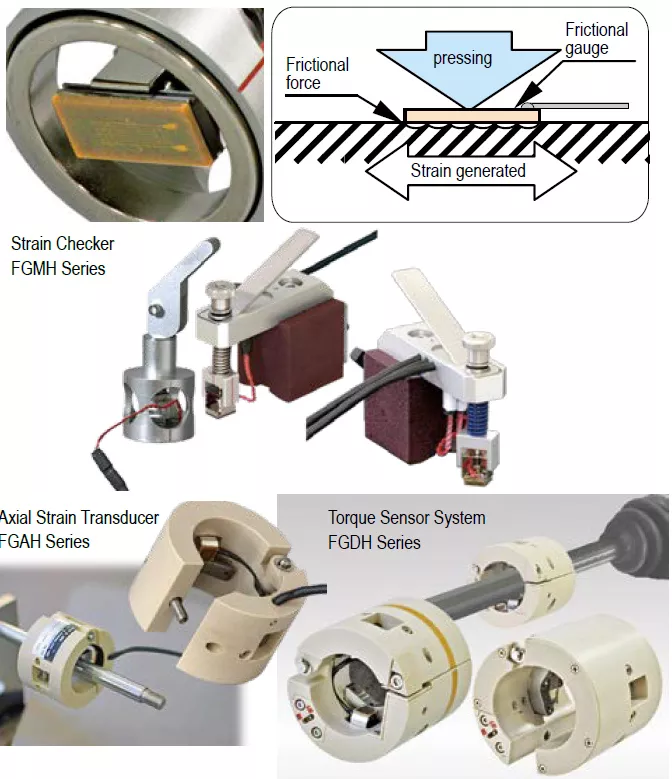

Reusable strain gauges: Friction measurement strips

Friction measuring strips are an innovative type of strain gauge that offer distinct advantages due to their reusable design. These strips feature a soft rubber layer combined with a strong magnet, allowing them to securely attach to the metal surface of the test sample without the need for adhesive.

Features and Benefits:

- Measurement principle: The strip measures strain resulting from the friction between the rubber layer and the contact surface of the sample.

- Reusability: Thanks to the magnetic attachment, these strain gauges can be easily removed and reused, offering long-term cost-effectiveness.

- Flexibility: The measuring tip can be swiftly repositioned, making it ideal for both preparatory and supplementary measurements.

- Temperature range: These strips are designed for use in environments with a maximum operating temperature of 60°C, taking into account the magnetic force.

Strain gauge embedding for internal strain measurements

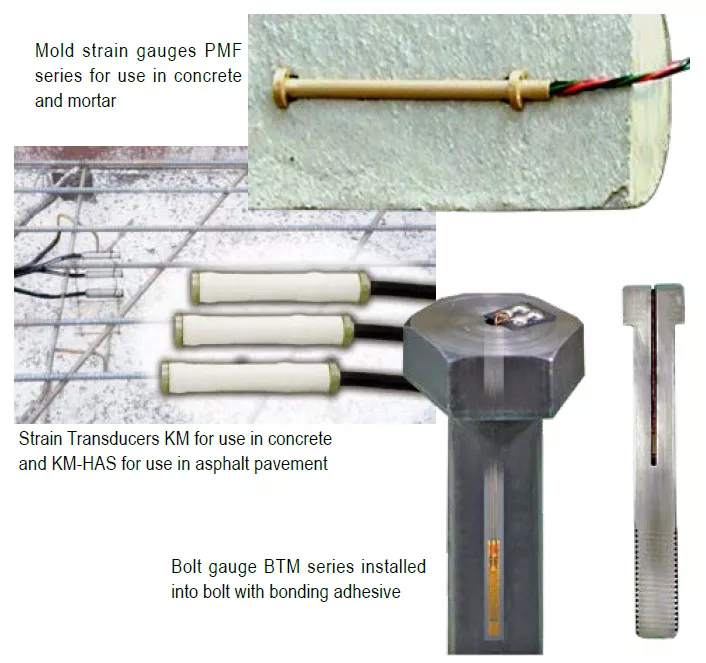

In addition to measuring surface tension, strain gauges can be embedded within materials to assess internal stresses. This method is particularly beneficial for materials like concrete, mortar, and asphalt.

Characteristics of embedded strain gauges:

- Early-stage measurements: By embedding strain gauges prior to material hardening, internal stresses can be monitored during the initial stages of the curing process.

- High-temperature applications: Certain embedded strain gauges are designed to withstand temperatures up to 200°C, making them ideal for use in asphalt and other high-temperature environments.

- Axial force measurement in bolts: A specialized technique allows for the measurement of axial forces in bolts through the integration of custom-designed strain gauges.

Advantages: Embedded strain gauges provide valuable insights into the structural behavior of materials both during and after curing. This capability is crucial for advanced analysis in construction and infrastructure projects.

More information

Do you have questions about strain gauges?

Need more information about strain gauges or misscien additional questions or a quotation? Contact our technical experts, who will be happy to help you.