SmartBrick monitors the inclination of Leiden's bridges

Smart industrial IoT measurement solution for condition monitoring applications.

Condition monitoring is a major part of predictive maintenance as implementing condition monitoring allows for maintenance to be scheduled and reventive actions taken to prevent damage, future failure and subsequent unplanned downtime of the machinery.

Excessive vibrations or high temperatures are often caused by component imbalance, misalignment, wear or improper equipment use. They can be early signs of impending machine failure. These can now be identified effortlessly without manual measurements or expensive wired equipment. The wireless measurement points measure triaxial vibrations and surface temperatures of rotating equipment such as pumps, motors and compressors.

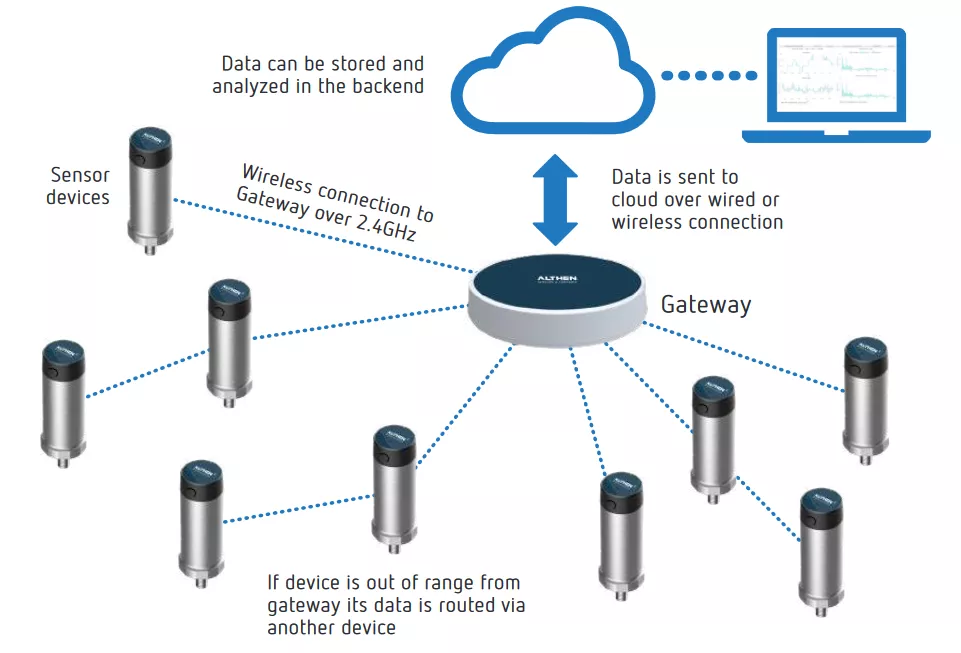

We provide a smart, IIoT measurement solution for condition monitoring applications. The system consists of wireless, battery-powered industrial measurement nodes and a gateway for communication to send data to the cloud. The nodes send data directly or via other nodes to the gateways. Data can therefore be sent to any cloud platform through a wired or wireless network. This way, you quickly and easily increase the availability of your machine.

Would you like to save yourself the programming effort of setting up your own cloud application? Althen offers you a ready-to-go solution!

Accept the marketing cookies to view this video.

Click here to change your consent.

The wireless IoT monitoring system consists of a network of sensor nodes, which can send their data via an IoT gateway to any computer network or cloud platform. We offer two different nodes: the industrial sensor nodes measure and monitor triaxial vibrations and surface temperature of (rotating) equipment, such as pumps, motors, agitators and mixers. The ambient nodes monitor air quality, temperature, humidity, ambient light, noise level and air pressure. The wireless battery-operated nodes can be easily and cost-efficiently mounted on existing equipment, but can also be part of large-scale mesh networks for collecting sensor data in smart buildings, cities and factories.

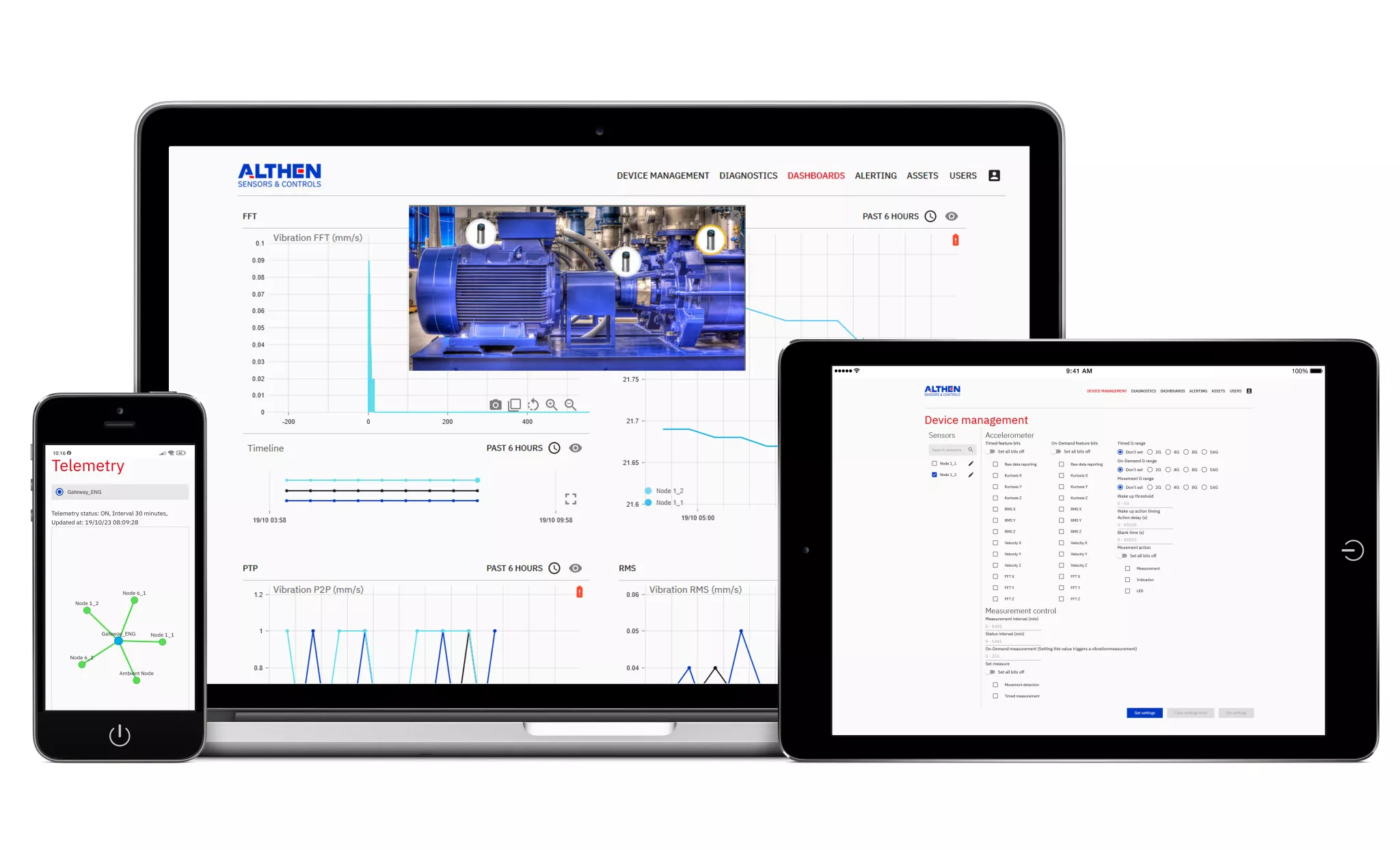

Rich data visualization, tailored to your needs:

Setting up and commissioning an IIoT solution: from selecting the platform with wireless acceleration sensors to monitoring and commissioning.

Application fields

How to retrofit your existing machines quickly and easily with IoT vibration monitoring solutions: With our plug-and-play solution combined with a comprehensive and clear dashboard your machine park will quickly turn from old to smart.

Althen IoT Monitor is the perfect IoT dashboard to collect and analyse you data. It offers a great choice of widgets for different visualizations and powerful filter and aggregation options such as fault detection, FFT analysis and many more.

Althen offers a variety of standard IIoT sensor hardware. Most sensors are based on the LORA communication and are battery powered, e.g. temperature-, vibration- and inclination sensors, CO2 sensors, routers and gateways.

Do you need advice or help with your IIoT measurement project?